Yes, you can cut concrete with an angle grinder, but selecting the right blade and using proper safety gear is essential. An angle grinder works best for small concrete jobs or detailed cuts where larger saws are impractical. Operators must prioritize safety, as improper use can lead to serious incidents. The table below highlights common risks associated with angle grinder use during concrete cutting:

Safety Incident | Consequences | Prevention Methods |

Abrasive Blade Shattering | High risk of fatality; serious injuries | Use diamond blades; inspect for damage; follow RPM guidelines |

Diamond-Blade Segment Loss | Fatal or severe injuries | Choose safety blades with strong welds |

Grinder Kickback | Fatal or severe injuries | Avoid fatigue; use correct blade; keep proper posture |

Always choose a diamond blade for concrete and stay alert to prevent accidents with an angle grinder.

Key Takeaways

Use a diamond blade with your angle grinder for faster, cleaner, and safer concrete cuts.

Choose a corded grinder for heavy, continuous work and a cordless model for mobility and quick jobs.

Always wear full safety gear, including goggles, gloves, hearing protection, and a dust mask to protect yourself.

Cut concrete in shallow passes, let the blade do the work, and use dust control methods to stay safe and keep your tool in good shape.

Pick a trusted brand with good power, safety features, and warranty to ensure reliable performance and long tool life.

Angle Grinder Basics

Types of Angle Grinders

Selecting the right angle grinder depends on the job requirements and the user's environment. Two main types exist: corded and cordless. Each type offers unique advantages for concrete cutting.

Corded angle grinders deliver continuous, reliable power directly from an electrical outlet. These models maintain high RPMs, often reaching up to 12,000, and provide strong torque. This makes them the best for professional use, especially during heavy-duty or prolonged concrete cutting. Corded grinders weigh less because they lack batteries, which helps reduce user fatigue during extended sessions. They also cost less initially and over time, making them a practical choice for professionals who need efficiency and durability.

Cordless angle grinders excel in mobility. They run on batteries, usually 18V to 36V, and allow users to work in remote or outdoor locations without access to power outlets. Cordless models eliminate trip hazards from cords, which improves safety on busy job sites. However, their power output is lower, and runtime is limited to about 20-30 minutes per charge. Battery maintenance and replacement add to the overall cost. For tasks that require freedom of movement or quick, intermittent cuts, cordless grinders are the best for professional use in the field.

Tip: For continuous, demanding concrete work, a corded angle grinder is the best for professional use. For remote or quick jobs, a cordless model offers unmatched convenience.

Power and Size

The power rating and size of an angle grinder directly affect its performance on concrete. Professionals recommend a minimum power of 1.2 kW, with 1.4 kW or higher being optimal for efficient cutting. Higher power enables faster work, reduces motor strain, and extends the life of consumables. Corded grinders consistently deliver this power, making them the best for professional use when cutting dense materials like concrete. Cordless models, while portable, generally offer lower power and shorter runtimes, which can limit their effectiveness on large or tough jobs.

Choosing the right disc size also matters:

Disc Size | Best Use Case | Recommendation |

115mm | Precision/detail work | Best small angle grinder |

125mm | Small-scale concrete cutting | General DIY and light trade |

230mm | Large/professional projects | Best large angle grinder, best for professional use |

A 115mm angle grinder suits precision tasks, while a 125mm model handles most small-scale jobs. For large or professional concrete cutting, a 230mm angle grinder stands out as the best for professional use. Professionals should match the grinder size and power to the demands of each project for safe, efficient results.

Best Angle Grinder Brand

What to Look For

Selecting the best angle grinder brand for concrete cutting requires careful attention to several features. Power and size matter most, especially the amp rating and disc diameter. A heavy-duty angle grinder with at least 9 amps and a disc size between 4.5 and 7 inches delivers reliable performance for concrete work. Ergonomics play a vital role in reducing fatigue during long sessions. Brands that offer anti-vibration grips, comfortable handles, and lightweight designs help professionals maintain control and comfort.

Safety features such as adjustable guards, lock-off switches, and paddle switches protect users from accidental starts and flying debris. Variable speed control allows professionals to adapt the grinder’s speed to different materials, preventing overheating and improving precision. Dust protection features are essential for concrete cutting, as fine particles can damage the motor. Quick wheel change systems and side handles add convenience and control. Warranty terms and brand reputation also influence the decision, with professionals preferring brands that offer strong support and reliable after-sales service.

Tip: Professionals should always check for dust protection and restart protection when choosing a heavy-duty angle grinder for concrete projects.

Top Brands for 2025

The best angle grinder brand for concrete cutting in 2025 stands out for durability, power, and user satisfaction. Leading brands include DeWalt, Makita, Bosch, Metabo, and Milwaukee. These manufacturers consistently deliver models that are best for professional use, offering high performance and advanced safety features.

DeWalt: Known for powerful motors and top safety systems. The DWE43116 and DWE402 models rank as best for professional use, featuring dust ejection systems and long brush life.

Bosch: Offers grinders like the GWS13-50VSP and GWS8-45, which provide variable speed, ergonomic design, and durability. Professionals value Bosch for reliable mid-range and premium options.

Makita: The PC5010CX1 excels in concrete surface grinding, with a 12-amp motor and vibration-dampening system. Makita grinders include concrete shrouds for dust collection, making them best for professional use.

Metabo: Delivers heavy-duty angle grinder models such as the WEV15-125, featuring overload protection and safety slip clutches. Metabo grinders are trusted in industrial concrete cutting equipment.

Milwaukee: Recognized for robust build quality and innovative features, Milwaukee grinders suit demanding professional environments.

Brand | Notable Model | Power (Amp) | Key Features | Warranty Duration |

DeWalt | DWE43116 | 13 | Dust ejection, safety guard | 2 years |

Bosch | GWS13-50VSP | 13 | Variable speed, ergonomic | 2 years |

Makita | PC5010CX1 | 12 | Vibration dampening, shroud | 3 years |

Metabo | WEV15-125 | 13.5 | Overload protection, clutch | 3 years |

Milwaukee | 2886-20 | 11 | Brushless motor, durability | 5 years |

Angle grinder recommendations for concrete cutting in 2025 focus on these brands due to their proven reliability, strong warranties, and advanced safety features. Professionals consistently rate these brands as best for professional use and heavy-duty angle grinder tasks.

Best Angle Grinders for Concrete

Corded Models

Professionals often select corded angle grinders for concrete cutting due to their consistent power and reliability. The best corded angle grinders deliver high performance, making them suitable for demanding tasks. The DeWalt DWE402 stands out with its 11-amp motor and 10,000 RPM, offering durability and a user-friendly design. Users appreciate its cooler motor operation and three-year warranty. The Makita GA7021, with a 15-amp motor and a 7-inch disc, handles tough materials and extensive milling. Although heavier, it remains a top choice for those who need the best corded angle grinders for large projects.

Bosch GWS13-50 provides exceptional dust collection and ergonomic handling, making it ideal for both professionals and DIY users. Metabo WEV 15-125 Quick HT features a quick disc change system and ergonomic design, which ensures comfort during extended use. The table below summarizes key features of these best corded angle grinders:

Model | Motor Power | RPM | Disc Size | Key Features |

DeWalt DWE402 | 11-amp | 10,000 | 194 mm | Durability, cooler motor, 3-year warranty |

Makita GA7021 | 15-amp | 6,600 | 7-inch | Large disc, reliable, handles tough material |

Bosch GWS13-50 | 13-amp | 11,500 | N/A | Dust collection, ergonomic, versatile |

Metabo WEV 15-125 Quick HT | 13-amp | N/A | 125 mm | Quick disc change, comfort, extended use |

Tip: To extend the life of any corded angle grinder, users should clean the tool after each use, inspect for wear, lubricate moving parts, and store it in a dry place.

Best Cordless Angle Grinders

Cordless angle grinders offer unmatched mobility for concrete work in locations without easy access to power outlets. The best cordless angle grinders combine portability with impressive power and safety features. The DeWalt 20-Volt MAX Brushless model leads the market, providing long battery life and efficient brushless motor technology. Makita’s 18V LXT Cordless grinder delivers reliable performance and a comfortable grip, making it a favorite for professionals who need flexibility.

Milwaukee 2886-20 stands out among the best cordless angle grinders for its robust build and advanced electronics, which protect against overload and overheating. Users seeking a lightweight option often choose the Bosch GWS 750, while those needing a comprehensive kit prefer the Metabo HPT MultiVolt system.

Note: Regular maintenance, such as cleaning after use, inspecting carbon brushes, and checking the battery, ensures the best cordless angle grinders remain safe and effective.

Choosing the Right Blade

Diamond Blades

Professionals rely on diamond blades when cutting concrete with an angle grinder. These blades contain synthetic diamonds embedded in the cutting edge, which deliver superior performance compared to traditional abrasive blades. Diamond blades cut faster, last longer, and produce cleaner results. Operators achieve professional-quality finishes with minimal chipping, making these blades essential for construction and masonry work.

Advantage | Explanation |

Enhanced Cutting Efficiency | Diamond blades cut faster and more efficiently, reducing project time and labor costs. |

Increased Durability | Synthetic diamonds extend blade lifespan, outperforming conventional abrasive blades. |

Cleaner Cuts | Minimal chipping ensures smooth, professional results. |

Versatility Across Materials | Effective for concrete, brick, stone, and asphalt. |

Diamond blades come in several types, each designed for specific tasks:

Blade Type | Description and Advantages |

Segmented Blades | Slots for cooling and debris removal; ideal for hard materials like concrete and masonry. |

Continuous Rim Blades | Provide clean, chip-free cuts; best for tile, ceramic, and glass. |

Turbo Blades | Serrated edges combine benefits of segmented and continuous blades; versatile for various materials. |

Operators should select the blade type based on the material and desired finish. Wet cutting uses water to cool and lubricate the blade, reducing dust and extending blade life. Dry cutting suits quick, small jobs but may wear the blade faster and create more dust. Choosing the correct blade and cutting method ensures efficient, precise, and durable results.

Tip: Enter the material smoothly and avoid excessive force. The sharpness of the diamonds does the work. Always wear gloves, goggles, and a respirator when using an angle grinder.

Blade Size and Fit

Selecting the right blade size for an angle grinder impacts both efficiency and safety. Smaller blades, such as 4.5-inch or 5-inch, offer better maneuverability and control, which improves precision and reduces risk. Larger blades, like 7-inch models, provide greater stability and faster material removal. These blades suit grinding or leveling tasks rather than detailed cutting.

Smaller blades (4.5"–5") improve safety and precision during concrete cutting.

Larger blades (7") deliver stability and speed, ideal for heavy grinding.

Matching the grinder’s RPM rating to the blade’s rating is critical for safe operation.

Using the correct blade size and type reduces risks such as kickback, overheating, and blade failure.

Multiple shallow passes prevent overheating and kickback, extending blade life.

Operators must ensure the blade fits securely on the angle grinder and matches the tool’s specifications. Proper mounting, dust control, and personal protective equipment protect users from injury. Choosing the right blade size and fit maximizes the angle grinder’s performance and safety during concrete cutting.

How to Cut Concrete

Preparation

Proper preparation ensures a safe and efficient concrete cutting process. Operators should always select the correct tool for the job. For small or detailed work, a corded angle grinder provides consistent power, while a cordless model offers flexibility for outdoor or remote locations. Before starting, users must inspect the grinder and blade for any signs of damage. They should follow all manufacturer instructions, including emergency procedures and troubleshooting steps.

A thorough checklist for preparation includes:

Choose the right angle grinder and diamond blade for concrete cutting.

Inspect the grinder, wheel, and all attachments for cracks or wear.

Confirm that all guards and handles are securely in place.

Review manufacturer guidelines and ensure all operators have proper training.

Secure the workpiece using clamps or a vice to prevent movement.

Wear personal protective equipment such as safety glasses, gloves, face shield, and hearing protection.

Keep the work area clear of clutter and tripping hazards.

Allow the grinder to reach full speed before making contact with the concrete.

Store unused grinders and blades in a safe, dry location.

Clean and maintain the grinder regularly, checking bolts, nuts, and belts for wear.

Tip: Cover nearby surfaces with plastic sheets to protect them from dust and debris before starting any cutting task.

Cutting Steps

Cutting concrete with an angle grinder requires a methodical approach. Operators should always use two hands on the tool for maximum control. Both corded and cordless grinders can handle concrete, but users must never exceed the maximum RPM rating of the blade. The following steps outline a safe and effective process:

Mark the cutting line clearly on the concrete surface.

Fit the angle grinder with the appropriate diamond blade, ensuring a secure fit.

Position the grinder at a 15-30 degree angle to the surface.

Start the grinder and let it reach full speed before touching the concrete.

Make shallow passes, cutting only a small depth at a time. Avoid cutting too deep in one pass, as this can cause blade overheating and dangerous kickback.

Let the blade do the work. Do not force the grinder through the material.

Use dust control measures, such as a vacuum system or wet cutting method, to minimize airborne particles.

Take frequent breaks to inspect the blade and tool for signs of wear or overheating.

Never use a cutting wheel for grinding or remove the safety guard during operation.

For cordless grinders, monitor battery life and replace or recharge as needed to maintain consistent performance.

Common mistakes include skipping safety gear, using the wrong blade, or neglecting dust control. Operators should always prioritize safety and follow best practices to prevent accidents.

Note: Forcing the grinder or skipping dust control can lead to tool damage and unsafe conditions. Always use the correct blade and let the tool work at its own pace.

Cleanup

Effective cleanup after cutting concrete protects both health and equipment. Operators should first turn off all cutting equipment and dust collection systems. Allow dust to settle before beginning the cleaning process. Sweeping or using a low-pressure air blower removes visible debris. Wet mopping the area captures remaining dust particles and prevents them from becoming airborne again.

A recommended cleanup procedure includes:

Turn off and unplug all angle grinders and dust collection devices.

Wait for dust to settle before starting cleanup.

Sweep or blow away loose dust and debris from the work area.

Wet mop the floor to capture fine dust particles.

Empty dust collection containers into sealed bags for safe disposal.

Clean and maintain dust control equipment for future use.

If necessary, hose down the area to further reduce dust and restore cleanliness.

Callout: Final cleanup is crucial to avoid hazards and delays. Proper disposal of dust and debris keeps the workspace safe and ready for the next project.

Safety Tips

Protective Gear

Operators must always wear a full suite of safety features when cutting concrete with an angle grinder. OSHA Standard 1926.300(c) requires personal protective equipment to protect against flying debris and harmful dust. The following items form the foundation of a full suite of safety features:

Safety glasses

Face shield

Gloves

Hearing protection

These items shield the eyes, face, hands, and ears from hazards. Angle grinders produce high noise levels, often reaching up to 109 dBA, which is as loud as a rock concert. Hearing protection is essential, especially during extended use. The table below compares noise levels of common workshop tools:

Tool | Noise Level (dBA) | Notes |

Angle Grinder | Up to 109 | Among the loudest tools; requires protection |

Circular Saw | 108-113 | Comparable noise level |

Drill | 99 | Quieter, but still loud |

A full suite of safety features also includes anti-vibration gloves and steel-toed boots for added protection. Operators should check that all guards and handles are in place to reduce the risk of kickback. Using a grinder with built-in kickback control further enhances safety. These features work together to prevent injuries and maintain control during operation.

Tip: Never operate an angle grinder without a full suite of safety features. Proper gear reduces the risk of kickback and other hazards.

Dust Control

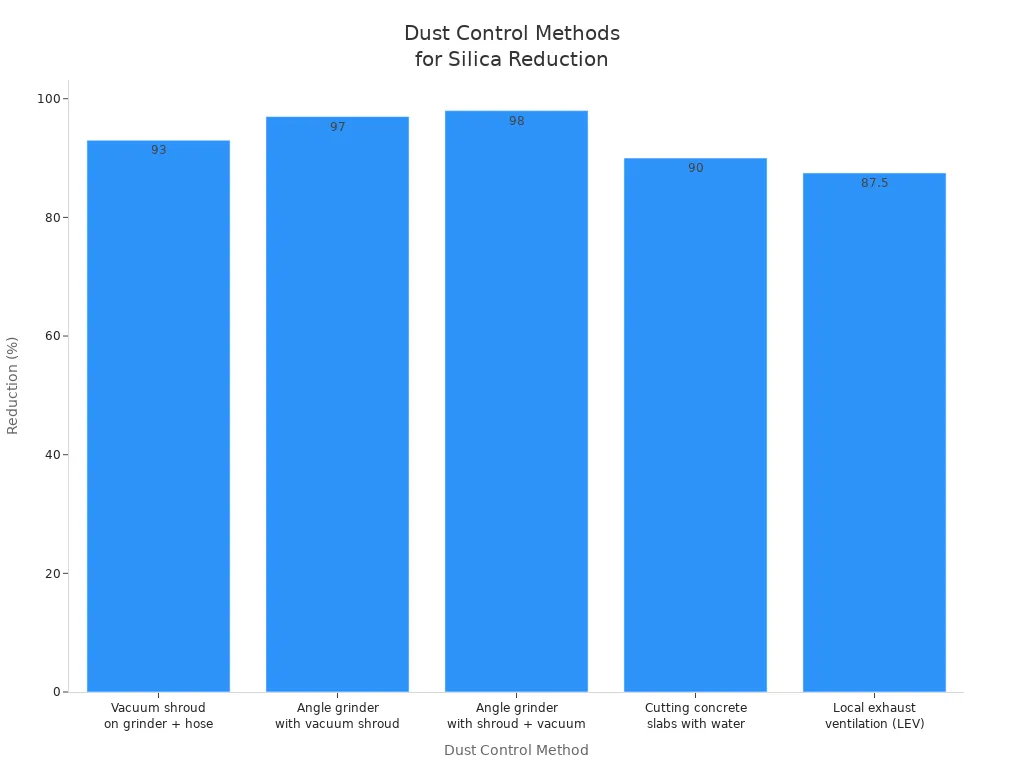

Concrete cutting generates fine silica dust, which poses serious health risks. A full suite of safety features must include effective dust control. Studies show that using a vacuum shroud with a hose can reduce respirable silica exposure by over 93%. The table below highlights the effectiveness of different dust control methods:

Dust Control Method | Reduction in Respirable Silica Exposure |

Vacuum shroud on grinder + hose | ~93% |

Angle grinder with vacuum shroud | >97% |

Angle grinder with shroud + vacuum | ~98% |

Cutting concrete slabs with water | ≥90% |

Local exhaust ventilation (LEV) | 80-95% |

Operators should use wet cutting methods or a vacuum dust collection system as part of a full suite of safety features. Respiratory protection, such as a NIOSH-approved dust respirator, is also necessary. These controls help keep silica exposure below OSHA limits. Using a grinder with kickback control and a full suite of safety features further reduces risks. Proper dust control not only protects health but also prevents kickback by keeping the work area clear.

Note: Always combine dust control with a full suite of safety features and kickback control to ensure the safest possible operation.

Limitations and Risks

When to Use Other Tools

Angle grinders offer versatility for many concrete cutting tasks, but they have clear limitations. These tools lack water cooling, which leads to rapid blade wear and excessive dust. For heavy-duty or deep concrete cuts, a professional should select a specialized concrete saw. Walk-behind saws use water cooling to keep blade temperature low and extend blade life. They also provide deeper, more precise cuts, making them ideal for large-scale jobs.

Certain situations call for different tools. Cutoff tools work better in confined spaces because they allow one-handed operation and improved maneuverability. When a job requires delicate or highly accurate cuts, cutoff tools provide better control due to their lower horsepower. Angle grinders excel at versatile fabrication tasks but require two hands and produce more power, which increases the risk of kickback. Reinforced or high-strength concrete presents another challenge. Standard diamond blades may struggle with rebar, and improper tool selection can cause excessive heat, blade damage, and safety hazards. For these demanding materials, a professional should use specialized diamond-embedded blades or heavy-duty equipment.

Tip: Always match the tool to the job. For tight spaces, accuracy, or reinforced concrete, consider alternatives to an angle grinder.

Common Hazards

Cutting concrete with an angle grinder exposes operators to several hazards. Kickback remains the most frequent and dangerous risk. Loss of control from kickback can cause severe injuries, especially if the operator lacks experience or proper training. Grinding disc breakage or chipping can send projectiles flying, leading to eye injuries or deep cuts. Incorrect fitting or setting of the disc increases the chance of accidents and kickback.

Operators face additional risks:

Contact with the spinning wheel can cause severe cuts or amputations.

Loose clothing or hair may become entangled in rotating parts.

Sparks can ignite flammable materials, creating fire hazards.

Faulty equipment increases the risk of electric shock.

Long-term exposure to vibration may cause hand-arm vibration syndrome.

Silica dust and high noise levels threaten respiratory and hearing health.

Proper maintenance and regular inspection of equipment reduce these risks. Essential personal protective equipment includes safety goggles, gloves, hearing protection, and dust masks. Removing the safety guard or ignoring kickback control features significantly raises the chance of injury. Professional operators always use grinders with built-in kickback control and follow strict safety protocols.

Note: Kickback control, proper PPE, and regular training form the foundation of safe angle grinder operation.

Best Angle Grinder for the Money

Value Picks

Many homeowners and DIY enthusiasts want reliable performance without overspending. According to recent consumer reports, the Porter-Cable PC60TAG and PC60TPAG models stand out as the best angle grinder for the money. These models offer affordability, solid build quality, and a 1-year warranty. Both feature motors rated at 6 or 7 amps and run at 11,000 RPM, making them suitable for most home and garage projects. The cast metal gear case adds durability, while the lightweight design ensures easy handling.

The Hitachi G12SR4 also ranks highly for value. It comes with a storage case and multiple discs, which increases its appeal for users who want a complete kit. This model provides reliable performance for light concrete cutting and general grinding tasks. For those searching for the best for serious diy, these grinders deliver dependable results at a reasonable price.

Tip: For occasional concrete cutting or general use, value models like Porter-Cable and Hitachi offer the right balance of price and performance.

Budget vs. Premium

Choosing between budget and premium angle grinders depends on the user's needs. Budget models work well for light, occasional tasks. Premium models suit professionals or anyone tackling frequent, heavy-duty concrete cutting. The table below highlights the main differences:

Aspect | Premium Angle Grinders | Budget Angle Grinders |

Durability | Built with high-quality materials; last longer | Use less expensive materials; wear out faster |

Performance | Maintain power after repeated use | Power drops with heavy use |

Safety Features | Include advanced guards and overload protection | May lack key safety features |

Concrete Cutting | Best for frequent, tough jobs | Good for light, occasional work |

Warranty | 3-5 years | 1 year or less |

Cost | Higher upfront investment | Lower initial price |

Premium grinders, such as those from Makita or DeWalt, provide consistent power, advanced safety, and longer warranties. Budget models, like Porter-Cable and Hitachi, offer the best angle grinder for the money for users who do not need professional-grade durability. Buyers should match their choice to the demands of their projects.

Cutting concrete with an angle grinder is possible when users select the correct blade and follow strict safety steps. Professionals recommend diamond blades designed for concrete and advise wearing goggles, gloves, and a dust mask. Top brands such as DeWalt, Makita, Bosch, Metabo, and Milwaukee offer reliable models for both corded and cordless use.

Always inspect the angle grinder and blade before each job. Maintain a clear work area and use dust control methods to protect health.

For large or complex projects, they should consult a professional to ensure safe and precise results.

FAQ

Can an angle grinder cut reinforced concrete?

An angle grinder can cut reinforced concrete with a diamond blade. Operators must use blades rated for cutting through rebar. For thick or heavily reinforced slabs, professionals recommend a concrete saw for better efficiency and safety.

What blade should they use for concrete cutting?

Operators should select a diamond blade designed for concrete. Segmented diamond blades work best for fast, clean cuts. Always check the blade’s RPM rating and compatibility with the angle grinder model.

How deep can an angle grinder cut concrete?

Most angle grinders cut concrete up to 1.5 inches deep with a standard 4.5-inch or 5-inch blade. Larger grinders with 7-inch blades reach depths of 2.5 inches. For deeper cuts, professionals use specialized concrete saws.

Is wet cutting possible with an angle grinder?

Wet cutting is possible with some angle grinder models. Operators attach a water feed system to reduce dust and cool the blade. Always verify that the grinder supports wet cutting before starting the job.

What safety gear is required when using an angle grinder?

Operators must wear safety glasses, gloves, a face shield, and hearing protection. Respirators protect against silica dust. Steel-toed boots and anti-vibration gloves provide additional safety. Always use the angle grinder’s guard and dust control system.