The main difference between an angle grinder and a regular grinder lies in their design and intended use. An angle grinder features a handheld build and uses interchangeable discs that spin at high speeds, making it ideal for cutting, grinding, and polishing various materials. Regular grinders, such as bench or cylindrical grinders, tend to be stationary and focus on sharpening or shaping metal. Understanding the unique features of an angle grinder, like speed control and specialized disc types, helps users select the right tool for specific tasks. This knowledge improves efficiency and safety during diy projects and professional work. When users match the correct angle grinder or grinder with speed control to the job, they reduce errors and increase productivity. Choosing the appropriate tool for diy projects or workshop jobs ensures better results and safer operation.

Key Takeaways

Angle grinders are handheld, powerful tools designed for cutting, grinding, and polishing many materials, while regular grinders are usually stationary and focus on sharpening or shaping metal.

Choosing the right grinder and disc type for your project improves safety, efficiency, and results; angle grinders suit heavy-duty and versatile tasks, and regular grinders excel at precision work.

Always wear proper safety gear like goggles, gloves, and protective clothing when using grinders to prevent injuries from sparks, debris, and kickback.

Cordless angle grinders offer great portability for jobs without power outlets, while bench and cylindrical grinders provide stable platforms for detailed and precise grinding.

Use grinders with speed control to match the material and task, avoid common mistakes like wrong disc use or excessive pressure, and regularly inspect tools for safe operation.

Angle Grinder

Design

An angle grinder stands out as a powerful, handheld cutting tool designed for heavy-duty tasks. Most models feature ergonomic handles and lightweight, impact-resistant bodies, making them easy to maneuver. The motor power ranges from 500W to 2500W, and the speed typically falls between 6,000 and 12,500 RPM. Users can choose between corded and cordless angle grinder options, with cordless angle grinder models offering greater portability for jobs away from power outlets. The disc size usually ranges from 4 to 9 inches, and the tool supports a variety of interchangeable discs for different applications. Safety features include wheel guards, electronic brakes, and anti-vibration handles. The table below highlights key design features:

Feature | Angle Grinder |

Purpose | Heavy-duty grinding, cutting, and material removal |

Size | Larger, bulkier, heavier |

Motor Power | Higher horsepower (often 1 HP or more) |

Speed (RPM) | 6,000 - 12,000 |

Disc/Bit Size | 4" - 9" diameter |

Control | Less precise, focused on power |

Weight | Heavier (often 4 lbs or more) |

Safety Features | Wheel guard, kickback protection, PPE required |

Versatility | Multiple wheels for various tasks |

Uses

Angle grinders serve many industries, including construction, metalworking, and automotive repair. Workers rely on them for cutting metals, cutting tile, cutting stone, and grinding and polishing surfaces. In construction, the angle grinder excels at cutting tile, cutting stone, and smoothing concrete. Metalworkers use it for cutting tool steel, grinding welds, and polishing metal. Woodworkers and DIY enthusiasts use the cordless angle grinder for shaping wood, removing paint, and artistic projects. The tool’s versatility comes from its ability to switch between cutting, grinding and polishing discs, making it essential for both professionals and hobbyists.

Tip: Always select the right disc for the job. For example, diamond wheels work best for cutting tile and cutting stone, while flap discs are ideal for grinding and polishing metal.

How Does an Angle Grinder Work

How does an angle grinder work? The tool uses a high-speed motor to spin a disc at thousands of revolutions per minute. The user holds the angle grinder with both hands, guiding the spinning disc against the workpiece. The cordless angle grinder allows for freehand use in tight spaces or outdoors. Sparks and debris often fly during operation, so users must wear safety glasses, gloves, and flame-retardant clothing. Before starting, users inspect the disc for cracks and ensure the guard is in place. They run the grinder at full speed before touching the material, keeping the disc at a 15 to 30-degree angle for best results. The angle grinder’s power and speed make it effective for cutting metals, cutting tile, and grinding and polishing a wide range of materials.

Regular Grinder

Types

Regular grinders come in several forms, each designed for specific tasks in workshops and industrial settings. The most common types include bench grinders, die grinders, cylindrical grinders, and specialty machines like cnc grinders and carbide grinders. Bench grinders are stationary tools mounted to a workbench, providing a stable platform for sharpening tools and cleaning metal. Die grinders are handheld and excel at precision work in tight spaces. Cylindrical grinders and cnc cylindrical grinder models handle more complex shaping and finishing of round objects, often used in manufacturing. Specialty café grinders and shop grinders focus on high-volume coffee grinding, while industrial grinders support mass production.

Grinder Type | Description | Ideal Uses | Key Features | Example Brands/Models |

Bench Grinder | Stationary, dual-wheel tool for general grinding | Sharpening, smoothing, cleaning metal | Stable, coarse/fine wheels, grinder with speed control | DeWalt, Jet |

Die Grinder | Handheld, lightweight, for detailed work | Polishing, deburring, intricate shaping | Portable, interchangeable bits | Makita, Milwaukee |

Cylindrical Grinder | Precision machine for round objects | Finishing shafts, rods, and rollers | High accuracy, automated options | Studer, Kellenberger |

CNC Grinder | Computer-controlled for complex shapes | Mass production, custom parts | Programmable, consistent results | Okuma, ANCA |

Carbide Grinder | Designed for carbide tool sharpening | Sharpening carbide-tipped tools | Specialized wheels, precise adjustments | Baldor, Palmgren |

Features

Bench grinders and die grinders offer different features to suit their intended uses. Bench grinders provide a stable, heavy-duty base, often bolted to a workbench. They use large wheels, usually 6 to 8 inches, and often include a grinder with speed control for different materials. Die grinders, in contrast, are lightweight and portable, making them ideal for detailed work. Cylindrical grinders and cnc cylindrical grinder models deliver high precision and can automate complex grinding tasks. Carbide grinders specialize in sharpening carbide tools with specialized wheels. Many regular grinders include safety shields, adjustable tool rests, and dust collection systems to improve safety and efficiency.

Note: Always check for grinder with speed control when working with different materials. This feature helps prevent overheating and ensures a smooth finish.

Applications

Regular grinders play a vital role in metalworking, woodworking, and manufacturing. Bench grinders handle sharpening tools like drill bits, chisels, and lawn mower blades. They also excel at cleaning metal surfaces and removing rust. Die grinders perform fine detailing, polishing, and deburring, making them popular for jewelry making and small repairs. Cylindrical grinders and cnc grinders are essential for producing precise round components in automotive and aerospace industries. Carbide grinders maintain the sharpness of carbide-tipped tools, supporting efficient cutting and shaping. Some regular grinders can even grind and shape stone, expanding their versatility in construction and fabrication.

Grinder Type | Common Applications in Metalworking |

Bench Grinder | Sharpening tools, rough shaping, cutting, polishing, cleaning metal |

Cylindrical Grinder | Finishing shafts, rods, rollers, precision shaping |

Die Grinder | Polishing, deburring, intricate detailing, small repairs |

CNC Grinder | Automated shaping, mass production, custom parts |

Carbide Grinder | Sharpening carbide tools, maintaining cutting edges |

Key Differences

Shape

The shape of each tool influences how users handle and control them.

The angle grinder features an angled head with a rotating disc that spins horizontally. This design supports heavy-duty tasks and allows for two-handed operation. The side handle and safety guard improve control and stability, especially during cutting or grinding.

Die grinders, a type of regular grinder, have a head parallel to the tool’s body. Their straight, compact shape makes them smaller and lighter. Users often operate these with one hand, which helps with precision in tight spaces but reduces stability and safety.

Bench grinders and cylindrical grinders have a stationary, bulky shape. These tools remain fixed to a workbench or floor, providing a stable platform for sharpening or shaping metal.

The cordless angle grinder keeps the same angled design as corded models but adds portability for jobs away from power outlets.

The angled shape of the angle grinder improves stability and safety for larger tasks, while the straight shape of die grinders favors precision and access in confined areas.

Disc Orientation

Disc orientation affects both safety and performance.

The angle grinder typically positions the disc on the left side for right-handed users. The disc rotates downward onto the material, directing sparks away from the user. This orientation helps maintain control and reduces the risk of injury.

Experienced users recommend cutting from halfway down and working upward. This method prevents the angle grinder from running away and improves accuracy.

The disc rotation should pull back on the tool, not push it into the workpiece. This approach enhances safety and control.

Regular grinders, such as bench grinders and cylindrical grinders, have discs or wheels that spin perpendicular to the work surface. The workpiece is held against the wheel, which remains stationary. This setup provides stability and precision but limits flexibility.

Disc Orientation Comparison Table

Tool Type | Disc Orientation | Typical Use Case |

Angle Grinder | Disc on left, spins downward | Freehand cutting, grinding |

Bench/Cylindrical Grinder | Wheel perpendicular to work surface | Sharpening, shaping, smoothing |

Die Grinder | Inline with tool body | Precision work, tight spaces |

Portability

Portability sets the angle grinder apart from most regular grinders.

Angle grinders are handheld, compact, and lightweight. Users can carry them to different locations, including households, job sites, and outdoor projects. The cordless angle grinder increases this flexibility, allowing work in areas without power outlets. These tools fit into tight spaces and handle a variety of tasks, from cutting tile to grinding metal.

Regular grinders, such as bench grinders, cylindrical grinders, and cnc grinders, are stationary. They require a dedicated workspace and remain fixed in one location. Their larger size and weight make them less portable but more stable for precision work.

Consideration | Angle Grinder (Portable) | Regular Grinder (Stationary) |

Portability | Highly portable, easy to move | Not portable, fixed in place |

Size | Compact, handheld | Large, bulky |

Flexibility | Works in many locations | Limited to workshop use |

Stability | Less stable | Very stable |

Workspace | Minimal space needed | Requires dedicated space |

Safety

Safety risks differ between angle grinders and regular grinders.

The angle grinder operates at high speeds, sometimes reaching 12,000 RPM. This speed increases the risk of severe injuries if mishandled. Kickback is a major hazard, where the disc suddenly pushes away from the workpiece, causing deep cuts or lacerations.

Flying debris, such as metal shards, can cause eye injuries. Discs may shatter or explode, sending fragments flying. Removing safety guards raises the risk of injury from debris and kickback.

Proper personal protective equipment (PPE) is critical. Users should wear safety goggles or face shields, heavy-duty gloves, hearing protection, and protective clothing.

Using the correct disc type and inspecting it for damage before use prevents accidents. OSHA statistics show that kickbacks are a leading cause of workplace injuries and fatalities related to angle grinders.

Professional safety tips include maintaining a firm two-handed grip, using the correct disc angle (15-30 degrees), and avoiding excessive pressure.

Common Safety Risks with Angle Grinders

High RPM operation causes sparks and airborne metal bits.

Kickback incidents can cause severe cuts.

Discs may shatter or explode.

Removing guards increases injury risk.

Lack of PPE leads to more severe injuries.

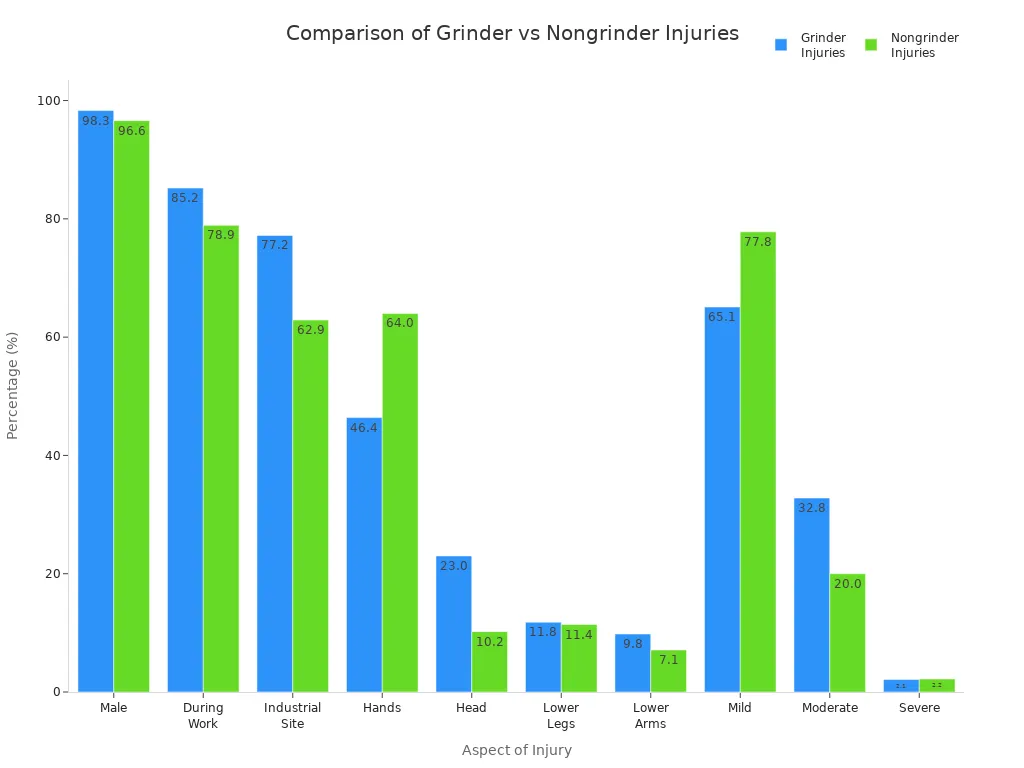

Statistical Data on Grinder Injuries

Aspect | Grinder Injuries (n=4,523) | Nongrinder Injuries (n=4,174) |

Gender (Male) | 98.3% | 96.6% |

Injuries During Work | 85.2% | 78.9% |

Injuries at Industrial Site | 77.2% | 62.9% |

Most Injured Body Parts | Hands (46.4%), Head (23.0%), Lower Legs (11.8%), Lower Arms (9.8%) | Hands (64.0%), Lower Legs (11.4%), Head (10.2%), Lower Arms (7.1%) |

Injury Severity Distribution | Mild: 65.1%, Moderate: 32.8%, Severe: 2.1% | Mild: 77.8%, Moderate: 20.0%, Severe: 2.2% |

Odds Ratios for Severe Injury (Adjusted) | Total: 2.07 (p<0.001), Torso: 5.54 (p=0.027), Arm: 1.78 (p<0.001), Multiple Injuries: 2.00 (p<0.001) | Reference group |

Note: Studies show that only 15.2% of injured users wore protective gloves. Using PPE reduces injury severity and speeds up recovery.

Tool Selection

Task Matching

Selecting the right grinder depends on the specific task and material. Users should consider several factors before choosing between an angle grinder and a regular grinder. The following list outlines the most important points:

Project Material: Users must match the grinder and disc type to the material, such as metal, concrete, tile, or wood. For cutting wood or metal, an angle grinder with the correct disc works best.

Task Nature: Cutting, grinding, polishing, shaping, or surface preparation all require different disc types and power levels. Angle grinders excel at heavy-duty cutting and grinding, while die grinders and cylindrical grinders handle precision work.

Power and RPM: Users should select a grinder with enough motor power and appropriate RPM for the job. A grinder with speed control offers flexibility for various materials.

Ergonomics and Comfort: Weight, grip, and vibration reduction matter for prolonged use.

Safety Features: Tools with guards, safety switches, and proper PPE help prevent injuries.

Mobility: Corded angle grinder models provide steady power, while cordless versions offer flexibility for diy projects in different locations.

Disc Selection: Using the correct disc—cutting, grinding, flap, wire brush, or diamond blade—improves results and safety.

Maintenance: Regular inspection and care of the grinder and discs ensure safe operation.

Angle grinders with smaller discs (4.5-5 inches) suit detailed work and polishing, while larger discs (7-9 inches) handle heavy-duty cutting and grinding. Die grinders and cnc cylindrical grinder models are ideal for fine polishing and shaping in tight spaces. For cutting wood or when users need to cut other materials, selecting the right attachment is essential.

Practical Advice

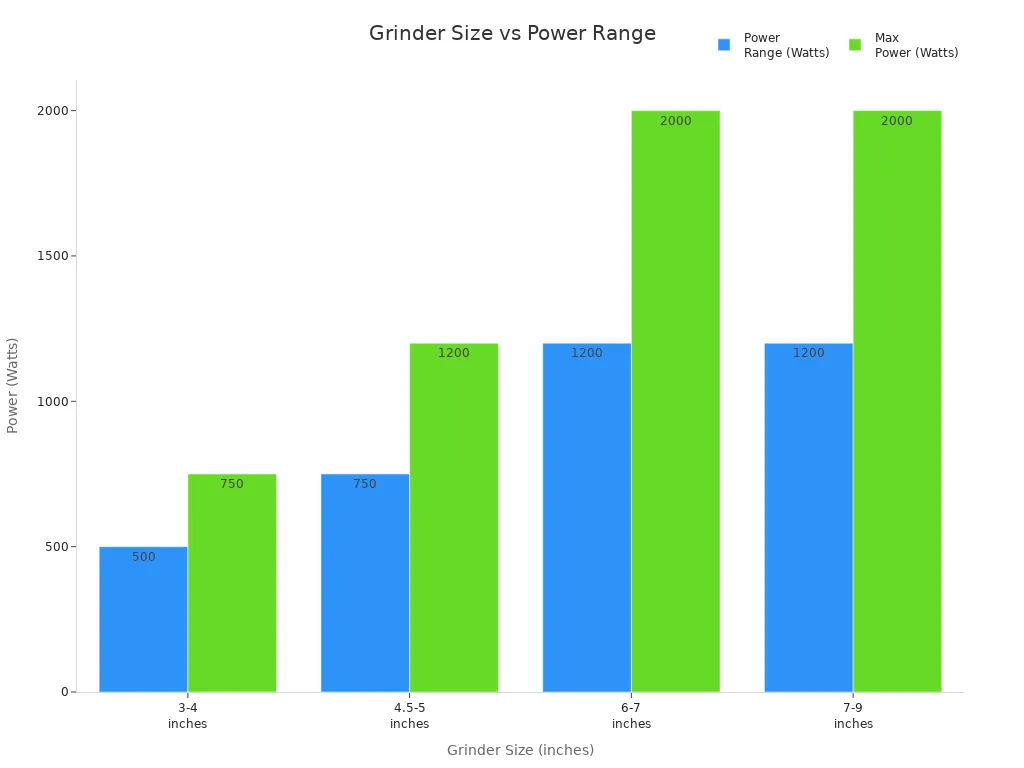

Experts recommend matching grinder size and power to the project’s scale and material thickness. The table below helps users compare grinder sizes, power, and best use cases:

Grinder Size (inches) | Recommended Use Case | Material Type | Power Range (Watts) | Budget Range (USD) | Notes on Control and Safety |

3-4 | Precision, small DIY repairs | Thin metal, delicate tasks | 500-750 | $50-$100 | Lightweight, easy to handle, precise |

4.5-5 | Most versatile, home renovation, general use | Medium metal, concrete | 750-1,200 | $100-$200 | Balanced power and control, standard discs |

6-7 | Heavy-duty tasks, construction | Thick metal, concrete | 1,200-2,000 | $200-$500 | More power, ergonomic design recommended |

7-9 | Industrial, very heavy-duty cutting | Very thick metal, slabs | 1,200-2,000+ | $200-$500+ | Large size, harder to control, safety concerns |

Users should avoid common mistakes, such as using the wrong disc, neglecting safety gear, or applying too much pressure. For diy projects, a 4.5-inch angle grinder provides versatility for cutting wood, metal, and even polishing. Corded angle grinder models suit continuous work, while cordless versions help with mobility. Cylindrical grinders, cnc grinders, and carbide grinder models are best for specialized shaping and sharpening tasks. Always inspect the grinder and attachments before use, and choose a grinder with speed control for better results.

Tip: Keep a set of attachments—cutting discs, grinding wheels, wire brushes, and sanding pads—to increase the angle grinder’s versatility for home improvement and diy projects.

Angle grinders offer handheld versatility for cutting, grinding, and polishing, while regular grinders like cylindrical grinders and cnc grinders provide stationary precision for flat surfaces. The table below highlights key differences:

Aspect | Surface Grinders (e.g., cnc cylindrical grinder) | Angle Grinder (corded angle grinder) |

Design | Stationary, precise | Handheld, portable |

Use | Flat surface finishing | Multi-material cutting, polishing |

Safety | Stable, safer | PPE required, sparks/debris |

For metal cutting, experts recommend power tools such as the corded angle grinder or specialized saws. Users should always match the grinder with speed control and disc type to the project. Prioritize safety, inspect carbide grinder parts, and maintain cnc grinders for best results.

Choose the right grinder for your needs, wear protective gear, and follow regular maintenance to ensure safe, efficient work every time.

FAQ

What makes an angle grinder different from a bench grinder?

An angle grinder is handheld and portable. It uses interchangeable discs for cutting, grinding, and polishing. Bench grinders, including cylindrical grinders, are stationary. They focus on sharpening and shaping metal. Angle grinders offer more versatility, especially with a corded angle grinder or cordless model.

Can a corded angle grinder cut through concrete?

Yes, a corded angle grinder can cut concrete when equipped with a diamond blade. This tool provides enough power and speed control for tough materials. Always use safety gear. For precision, cnc grinders or cnc cylindrical grinder machines work better in industrial settings.

Why choose a grinder with speed control?

A grinder with speed control lets users adjust RPM for different materials. This feature prevents overheating and improves results. Angle grinder models with speed control handle metal, tile, and wood. Cylindrical grinders and carbide grinder machines also benefit from adjustable speeds for specialized tasks.

What are the main uses for a carbide grinder?

A carbide grinder sharpens carbide-tipped tools. It maintains cutting edges for saw blades and drill bits. This grinder type is essential in workshops. Angle grinder models cannot match the precision of a carbide grinder or cnc cylindrical grinder for sharpening.

Are cnc grinders and cnc cylindrical grinder machines suitable for home use?

CNC grinders and cnc cylindrical grinder machines serve industrial needs. They offer automated, high-precision grinding. Most home users prefer an angle grinder or corded angle grinder for DIY projects. CNC machines require technical knowledge and a dedicated workspace.