Key Takeaways

You can cut many types of tile with an angle grinder by using the right diamond blade and safety gear.

Always wear eye protection, gloves, hearing protection, and a dust mask to stay safe while cutting tile.

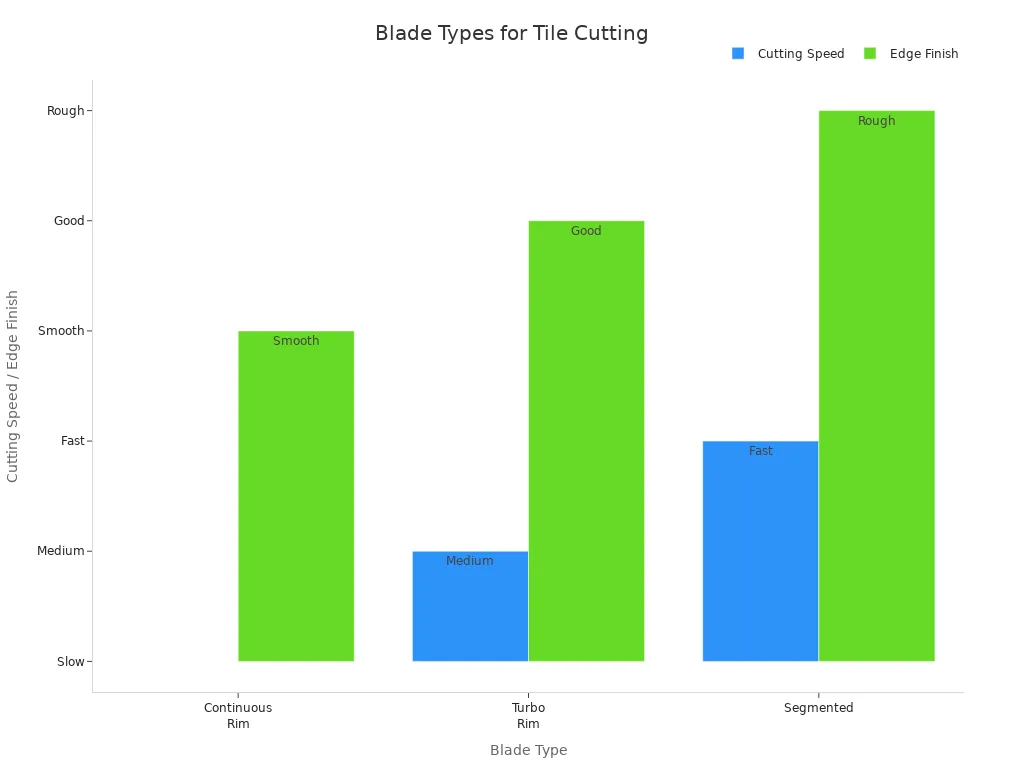

Use a continuous rim blade for smooth cuts on ceramic and porcelain, turbo blades for thick tiles, and segmented blades for stone.

Secure the tile firmly, mark your cut line clearly, and apply steady pressure while cutting to avoid chipping or cracking.

Angle grinders offer flexibility for curved or detailed cuts, but for perfect straight cuts, consider a wet tile saw or snap cutter.

What Is an Angle Grinder?

An angle grinder is one of the most popular handheld power tools you can use for cutting, grinding, and polishing. You hold it in your hands and control its movement, making it ideal for many tasks around your home or job site. The components and design of angle grinder models make them suitable for working with tough materials like tile, metal, and stone.

Angle Grinder Uses

You can use an angle grinder for a wide range of projects. Many people rely on it for cutting tiles, shaping stone, grinding metal, and even polishing surfaces. If you choose a cordless angle grinder, you get extra flexibility and can work in places without a power outlet. Some common uses include:

Cutting ceramic, porcelain, and stone tiles for kitchen or bathroom renovations.

Shaping granite or marble for countertops.

Grinding down welds or smoothing rough metal edges.

Polishing concrete floors or stone surfaces.

Professional brands like DeWalt, Makita, Bosch, and Metabo offer models with features designed for tile cutting. For example, the DeWalt DWE402 has an 11-amp motor and spins at up to 11,000 RPM, making it powerful enough for heavy-duty tasks.

How Does an Angle Grinder Work?

You power up the angle grinder, and its motor spins a disc at high speed. The spindle connects the motor to the disc, allowing it to rotate quickly. You can swap out discs for different jobs, but diamond discs are essential for cutting tile. The guard protects you from sparks and debris, while the side handle gives you better control.

Variable speed control lets you adjust the speed for different materials. You can use different disc sizes for more versatility. Cordless angle grinder models offer convenience, especially for tile cutting in tight spaces. The chart below shows how the speed of various angle grinder models compares:

Tool Type | Horsepower Range | Typical RPM Range | Usage Characteristics |

Angle Grinder | 3 to 7 hp | 8,000 to 19,500 RPM | High power and speed; suitable for heavy-duty cutting, grinding, shaping, and polishing; requires two-handed operation |

Cutoff Tool | Around 1 hp | Lower RPM | Lower power and speed; designed for precise, small-scale cutting; easier one-handed use |

If you want your angle grinder to last, clean it regularly, check the guard and disc before each use, and let it cool down after heavy work. Always wear safety gear and use diamond discs for tile cutting. You can use a cordless angle grinder for small cuts or rough shaping, but for perfect edges, consider a wet tile saw or snap cutter.

Can an Angle Grinder Cut Tile?

You can use an angle grinder to cut tile for many home improvement projects. This tool gives you flexibility and control, especially when you need to make curved or intricate cuts. Many professionals and DIY enthusiasts choose an angle grinder for retrofit jobs, such as modifying tiles around outlets, plumbing fixtures, or corners. You can also use it for straight cuts, shaping, and beveling tile edges.

Types of Tile You Can Cut

You can cut several types of tile with an angle grinder. The most common include:

Ceramic tiles: These are popular for walls and floors. You get smooth, chip-free cuts when you use a continuous rim diamond blade.

Porcelain tiles: These tiles are harder and denser. Turbo rim blades work well for thick porcelain tiles, giving you a balance of speed and edge quality.

Stone tiles: You can cut natural stone tiles like marble, granite, and slate. Segmented blades help you cut faster and remove chips, making them ideal for tough materials.

Mosaic tiles: You can use an angle grinder for small, detailed cuts on mosaic tiles, especially when you need to fit tiles around tight spaces.

Tip: Always match the blade type to the tile material. Continuous rim blades produce the smoothest finish on ceramic and porcelain. Turbo blades offer versatility for thick tiles. Segmented blades work best for stone and demolition tasks.

Blade Type | Cutting Speed | Edge Finish | Best For |

Continuous Rim | Slow | Smooth | Thin ceramic and porcelain tiles |

Turbo Rim | Medium | Good | Thick (20mm) porcelain tiles |

Segmented | Fast | Rough | Demolition or very hard materials |

You should select a high-quality diamond blade for your angle grinder. A 5-inch continuous rim diamond blade with a sintered diamond bond gives you precise, chip-free cuts on ceramic, porcelain, and thin stone tiles. This blade supports both dry and wet cutting. Wet cutting helps control dust and keeps the blade cool, which improves performance and blade life.

Limitations and Considerations

You need to consider several factors before you start cutting tile with an angle grinder. Here are some common issues and tips to help you get the best results:

Poor blade alignment can cause binding and dangerous kickbacks. Make sure the blade is straight and securely attached.

Chipping or cracking tiles often happens with hard materials. Score the tile before cutting and use the correct blade to reduce this risk.

Uneven cuts can ruin the look of your project. Use a straight edge and keep a steady hand during cutting.

Overheating blades may damage both the blade and the tile. Wet cutting and allowing the blade to cool help prevent overheating.

Short battery life interrupts your work if you use a cordless angle grinder. Keep extra batteries charged and ready.

Blade binding or stalling is hazardous. Select the right blade and avoid forcing the cut.

Dust buildup reduces visibility and can harm your health. Wear a dust mask and use wet cutting to minimize dust.

Safety concerns require you to wear goggles, ear protection, gloves, and a dust mask.

Note: You should avoid using an angle grinder on plastics like perspex, PVC, polycarbonate, or HDPE. These materials can melt, warp, or release toxic fumes. For tiles, you can cut most types safely if you use the correct diamond blade and proper technique.

You can use an angle grinder for cutting concrete, brick, slate, and other building materials. The right blade and safety gear make these tasks possible. If you wonder, "can an angle grinder cut stone?" or "can an angle grinder cut building materials?", the answer is yes. You need to follow safety guidelines and choose the correct blade for each material.

Diamond blades last much longer than ordinary grinding wheels. Manufacturers use sintered and hot press techniques to improve durability. Some blades come with a two-year warranty, showing confidence in their lifespan. You get more value and fewer blade changes during your project.

Angle grinders excel in small or detailed tile jobs. You can make curved cuts, intricate shapes, and radius cuts with ease. If you need portability and flexibility, especially for retrofit work, a cordless angle grinder is a smart choice. You can use a grinder with speed control for better results on different tile types.

How to Use an Angle Grinder for Tile

Tools and Materials Needed

Before you start, gather all the tools and materials you need. You want to make sure you have everything ready for a safe and accurate tile cutting experience. Here’s a checklist:

Angle grinder (corded or cordless angle grinder)

Diamond blade suitable for your tile type

Safety gear:

Eye and face protection (goggles or face shield)

Cut-resistant gloves (Kevlar® or Para-Aramid blends)

Hearing protection

Dust mask or respirator

Protective clothing (cape sleeves)

Clamps or a vice to secure the tile

Pencil or marker for marking cut lines

Straight edge or ruler

Rubbing stone or tile file for smoothing edges

Water spray bottle or wet sponge (for dust control and cooling)

Tip: Pick the right grinder for your project. A cordless angle grinder gives you flexibility, especially for small or detailed cuts.

Step-by-Step Guide

Follow these steps to cut tile safely and accurately with your angle grinder:

Mark the cutting line on the tile using a pencil or marker. Measure twice and use a straight edge for precision.

Attach the diamond blade to your angle grinder. Check that the blade is tight, undamaged, and matches your tile type.

Adjust the guard to protect yourself from debris and sparks.

Secure the tile on a stable surface with clamps or a vice. This prevents movement and breakage.

Put on all your safety gear before you begin.

Hold the angle grinder firmly with both hands. Start the tool away from the tile, then slowly bring the blade to the marked line.

Apply gentle, steady pressure. Let the blade do the work. Move the grinder continuously for straight cuts, and go slowly for curves.

Slow down as you finish the cut to avoid chipping the tile.

Turn off the grinder and wait for the blade to stop spinning before setting it down.

Smooth rough edges with a rubbing stone or tile file.

Note: Test your grinder and blade on a scrap tile first. This helps you check blade sharpness and cutting accuracy.

Safety Tips

Angle grinder safety is critical. You want to avoid common injuries like eye injuries, lacerations, and burns. Here are essential safety tips:

Always wear eye and face protection to guard against flying debris.

Use cut-resistant gloves and hearing protection.

Put on a dust mask to avoid inhaling hazardous dust.

Never remove the safety guard from your angle grinder.

Hold the grinder with both hands for better control.

Secure the tile firmly before cutting.

Do not force the grinder; let the blade do the work.

Disconnect power or remove the battery before changing blades.

Keep water away from the grinder to prevent electric shock.

Work in a well-ventilated area or use dust extraction systems.

Take breaks to let the blade cool and reduce dust.

Safety concerns are real. Most injuries happen when users ignore angle grinder safety rules or use the wrong blade. Always follow OSHA standards and manufacturer instructions.

Common Mistakes to Avoid | Why It Matters |

Using the wrong blade | Poor cuts, blade damage |

Weak marking lines | Inaccurate cuts |

Not securing the tile | Breakage, injury |

Forcing the grinder | Tile cracks, kickback |

Skipping safety gear | Risk of injury |

If you plan to use your angle grinder for cutting concrete or other tough materials, always check the blade type and safety gear. A cordless angle grinder works well for small jobs, but keep spare batteries charged. Remember, how to use an angle grinder safely and correctly makes all the difference in your results.

Angle Grinder vs. Other Tools

When you need to cut tile, you have several tool options. Each tool has strengths and weaknesses. Understanding these differences helps you choose the right one for your project.

Tile Saw Comparison

A wet tile saw gives you the fastest and most precise cuts, especially for large projects. You use water to cool the blade and reduce dust. This tool works best for straight cuts and thick tiles. Tile saws require setup and some skill, but they deliver clean, professional results. If you want to cut many tiles or need perfect edges, a wet tile saw is the top choice.

Tool Type | Cutting Speed & Use Case | Notes |

Angle Grinder | Quick, good for curves and corners | Fast, flexible, best for small or odd shapes |

Wet Tile Saw | Fastest, most precise, best for large projects | Needs setup, skill, and water; clean results |

Snap Cutter | Slowest, best for straight cuts on soft tiles | Simple, portable, only for straight cuts |

Tip: Use a wet tile saw for big jobs or when you want the cleanest finish.

Snap Cutter Comparison

A snap cutter is simple and portable. You score the tile and snap it along the line. This tool works well for straight cuts on ceramic or thin porcelain tiles. Snap cutters are affordable and easy to use, but they cannot handle curves or thick tiles. If you only need straight cuts for a small project, a snap cutter is a good choice.

Tool | Advantages | Disadvantages |

Angle Grinder | Cuts porcelain, ceramic, odd shapes, angles | Needs skill, risk of chipping |

Snap Cutter | Easy, portable, clean straight cuts, no mess | Only for straight cuts, not for thick tiles |

Note: Angle grinders with diamond blades let you make curved or detailed cuts that snap cutters cannot handle.

Can an Angle Grinder Cut Metal?

You may wonder, can an angle grinder cut metal? Yes, you can cut through metal using the right blade. Angle grinders handle many metals, including mild steel, stainless steel, iron, and hard alloys. For cutting metal, use abrasive cutting discs, diamond discs, or carbide discs. Thin discs cut faster and make cleaner cuts, while thicker discs last longer and provide more stability. Always check the blade type and thickness for your specific metal.

Metal Type | Suitable Blade Material | Blade Thickness |

Mild Steel | Abrasive Cutting Discs | 1/16" to 3/16" |

Stainless Steel | Diamond or Stainless Discs | 1/8" or thicker |

Iron | Carbide or Abrasive Discs | Standard to thick |

Hard Alloys | Diamond or Carbide Discs | Thicker for stability |

Safety first: Always wear protective gear when cutting metal. Sparks and heat are common.

You can use an angle grinder for many jobs, from tile to cutting metal. This tool is versatile, but it requires practice and the right blade for each material. If you want to make curved cuts or work in tight spaces, an angle grinder is a smart choice. For straight, clean cuts on many tiles, a wet tile saw or snap cutter may be easier.

You can achieve clean tile cuts with an angle grinder when you use the right blade and follow safety steps. Professionals recommend a corded angle grinder with at least 1.4 kW power and 11,000 RPM for best results. Always wear protective gear and secure your work. Angle grinders, including models with speed control, offer flexibility for intricate cuts that manual tile cutters or cnc grinders cannot match. Remember, dust extraction and the correct blade—like a carbide grinder or diamond segmented blade—make your project safer and easier. Choose your tool wisely for each job.

FAQ

What type of blade should you use to cut tile with an angle grinder?

You should use a diamond blade for tile cutting. This blade works well with ceramic, porcelain, and stone tiles. A continuous rim blade gives you the smoothest finish. Always check that your blade matches your tile material.

Can you use a corded angle grinder for long tile cutting sessions?

Yes, a corded angle grinder gives you steady power for long sessions. You do not need to worry about battery life. This tool works well for large projects or when you need to cut many tiles in one go.

How do you reduce dust when cutting tile with an angle grinder?

You can spray water on the tile or use a wet sponge to keep dust down. Some grinders with speed control help manage dust better. Always wear a dust mask and work in a well-ventilated area for safety.

What is the difference between a cnc grinder and a manual angle grinder?

A cnc grinder uses computer controls for precise, automated cuts. You use a manual angle grinder by hand for flexible, on-site work. Cnc cylindrical grinder models work best for high-volume or complex shapes in a workshop.

Can you use a carbide grinder for tile edges?

Yes, you can use a carbide grinder to smooth or shape tile edges after cutting. This tool helps you remove sharp spots and create a clean finish. Always wear gloves and eye protection when using any grinder.