In today's rapidly advancing technology world, high-power Brushless DC (BLDC) motors are pivotal components in various industrial applications. As the demand for more efficient, durable, and energy-saving motors continues to rise, questions around installation and maintenance of these motors, especially in specialized applications, have become more common. A recurring query in the B2B sector is: Can any engineers help install high-power BLDC motors?

In this article, we will discuss the intricacies of installing high-power BLDC motors, how skilled engineers can assist with this process, and the importance of working with a manufacturer like Hoprio Group, who offers not only top-tier products but also professional installation services to ensure optimal performance.

Understanding High-Power BLDC Motors

Brushless DC motors (BLDC motors) are widely known for their efficiency, longevity, and reliability compared to traditional brushed motors. Unlike brushed motors that rely on physical brushes for commutation, BLDC motors use electronic controllers to manage the rotor’s movement, making them more durable and energy-efficient.

High-power BLDC motors, such as the ones used in heavy-duty machinery, industrial tools, or cutting-edge robotics, require specific expertise for installation. These motors are often characterized by their large size, high torque, and the need for careful integration into complex systems.

Key Advantages of High-Power BLDC Motors

Efficiency: BLDC motors are typically more efficient than brushed motors, which translates into less energy consumption, reduced heat generation, and longer operational lifespans.

Maintenance-Free Operation: The absence of brushes in BLDC motors means fewer parts to wear down, leading to significantly lower maintenance requirements.

Precision Control: These motors offer smooth and precise speed control, making them ideal for applications that require fine adjustments.

High Power Density: BLDC motors can deliver a high amount of power in a relatively compact size, which is crucial for industrial equipment where space and power output must be optimized.

The Importance of Professional Installation

While the technology behind high-power BLDC motors is quite advanced, the installation process requires a high level of expertise. It’s not just about setting the motor into place; proper integration into the system requires knowledge of electrical systems, mechanical connections, and system-level testing. Here’s why it’s essential to engage skilled engineers for installation:

1. System Compatibility and Integration

Every application is unique, and high-power BLDC motors need to be integrated into specific machinery or systems. Engineers are responsible for ensuring that the motor is compatible with other system components such as controllers, sensors, and safety systems. They also need to ensure the motor’s mechanical connections (e.g., shaft coupling, mountings) are done accurately to avoid wear or system malfunction.

2. Correct Wiring and Electrical Configuration

The wiring of high-power BLDC motors involves more than just connecting power terminals. Engineers must ensure that the wiring is correctly configured for optimal performance, including proper grounding and the right connections for feedback signals (such as hall sensors) and power supplies. Incorrect wiring can lead to issues like motor overheating, erratic behavior, or even permanent damage to the motor.

3. Ensuring Safety Standards

Safety is paramount when handling high-power systems. Qualified engineers ensure that all safety protocols are followed, such as proper insulation of electrical components, safe handling of heavy parts, and the use of protective equipment during the installation. Additionally, they must ensure the motor is securely mounted and positioned to minimize the risk of mechanical failure.

4. Testing and Calibration

Once installed, the motor requires thorough testing to ensure it operates as expected. Engineers calibrate the motor to match the system’s requirements, making adjustments to the control settings, load handling, and performance thresholds. Proper testing is essential to guarantee the motor performs efficiently under real-world conditions.

How Hoprio Group Supports Installation

Hoprio Group stands out as a leading supplier of high-quality BLDC motors and provides an added advantage by offering professional support and installation services. With years of experience in manufacturing and distributing high-power BLDC motors, Hoprio’s dedicated teams are trained to ensure your motor is installed and configured to meet your specific needs.

Although Hoprio's on-site installation services may be regionally limited, they ensure all technical support is available remotely, offering guidance to engineers who are tasked with installation. Hoprio’s customer support team is also available to assist with any post-installation questions, making sure that your equipment operates smoothly for years to come.

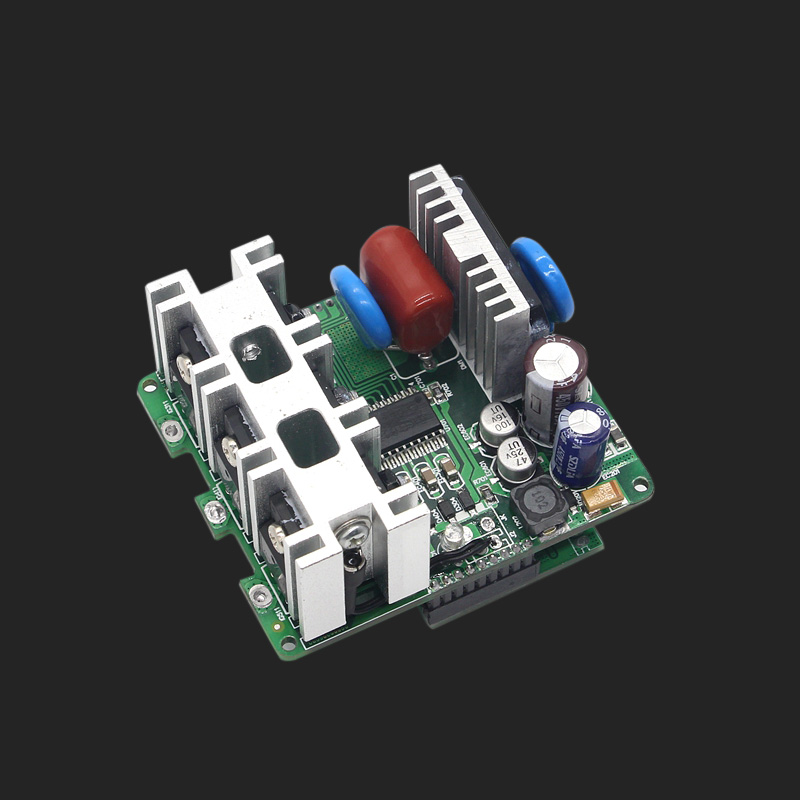

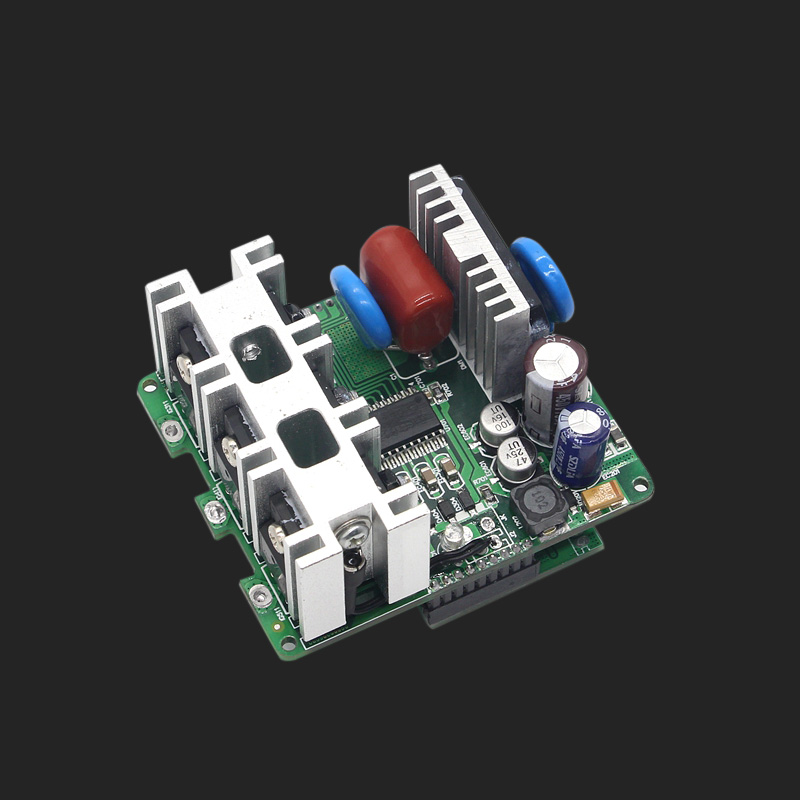

Examples of Hoprio’s High-Power BLDC Motors:

Hoprio also ensures that their engineers receive continuous training to stay ahead of the curve in terms of motor technology and installation techniques. This ongoing support is critical to maintaining customer satisfaction and ensuring that motors perform optimally throughout their operational lives.

Challenges in Installing High-Power BLDC Motors

While installation by skilled engineers is essential, there are several challenges that can arise during the process:

1. Motor Sizing and System Matching

Selecting the right motor size and power rating is crucial. A motor that’s too large can lead to unnecessary costs, while one that’s too small might not provide the required power output for the application. Engineers must take into account the application’s power needs, space constraints, and performance requirements when choosing the motor.

2. Environmental Conditions

BLDC motors used in industrial settings are often exposed to harsh environmental conditions such as temperature extremes, dust, moisture, and vibration. Engineers need to ensure that the motor is adequately protected, using enclosures or cooling systems where necessary.

3. Feedback and Control Integration

High-power BLDC motors often require feedback mechanisms (such as encoders or Hall sensors) to ensure smooth and precise operation. Engineers must ensure that these feedback systems are properly integrated and calibrated.

4. Cost and Time Constraints

In industrial settings, minimizing downtime is crucial. Engineers must efficiently install and test motors to ensure minimal disruption to ongoing operations.

Conclusion

The installation of high-power BLDC motors is a task that requires specialized knowledge and expertise. While it’s essential to have experienced engineers handle the installation to ensure that the motor functions efficiently, working with a company like Hoprio Group can further streamline the process. With their high-quality motor products, expert engineering teams, and commitment to providing ongoing support, Hoprio ensures that customers get the most out of their BLDC motors, both during installation and throughout their lifespan.

When you’re looking for reliable, powerful motors and professional installation support, Hoprio Group is the partner you can trust.