The main difference between an angle grinder and a cut-off grinder comes down to versatility and function. You use an angle grinder for grinding, sanding, and cutting, while a cut-off grinder focuses on making straight cuts through metal or other materials. Understanding these differences helps you choose the right power tool and prevents accidents.

Choosing the correct angle grinder or cut-off grinder improves your project results and keeps you safe.

Key Takeaways

Angle grinders offer versatility for cutting, grinding, sanding, and polishing many materials with different discs.

Cut-off grinders specialize in precise, straight cuts on metal and tile, working well in tight spaces with one hand.

Choose an angle grinder for heavy-duty, fast jobs and a cut-off grinder for delicate, accurate cuts.

Always use the right disc type and size for your tool and task to stay safe and get the best results.

Check safety guards and handles before use, wear protective gear, and maintain your tool regularly for safe operation.

Angle Grinder Basics

What Is an Angle Grinder

You use an angle grinder for many tasks in metalworking, construction, and home improvement. This power tool stands out because of its compact design and rotating disc. You can choose between corded, cordless angle grinder, or air-powered models. Battery-powered options lead the market, offering portability and convenience.

Here’s a quick look at the main design features that set the angle grinder apart:

Component | Purpose |

Rotating Disc | High-speed disc for cutting, grinding, sanding |

Motor | Powers the rotation; corded, cordless, or pneumatic |

Handles | Main and side handles for grip and control |

Safety Guard | Shields you from sparks and debris |

Variable Speed | Some models offer speed controls |

You get ergonomic handles and safety guards for better control and protection. The cordless angle grinder is especially popular for jobs that require flexibility and movement.

How Does an Angle Grinder Work

How does an angle grinder work? The motor spins the grinding disc at speeds between 6,000 and 12,000 RPM. This high speed lets you cut, grind, and sand tough materials. You can swap out the disc for different attachments, such as diamond blades for cutting wood or grinding discs for metal. The spindle lock makes changing discs quick and safe. Variable speed controls help you match the tool’s performance to your task, whether you need gentle sanding or aggressive grinding.

Tip: Always check the safety guard and handles before starting your cordless angle grinder. This keeps you safe and improves your results.

Uses of Angle Grinders

You can use an angle grinder for a wide range of jobs. The most common applications include:

Grinding and polishing metal surfaces

Cutting wood, metal pipes, tiles, and stone

Sanding rough edges or surfaces

Removing paint, rust, and corrosion

Shaping and carving wood for carpentry

Cleaning welds and prepping metal for fabrication

About one-third of angle grinder use focuses on metalworking, but you also see these tools in woodworking, masonry, and automotive repair. With the right attachments, your cordless angle grinder handles cutting wood, sanding, grinding, and polishing. You can switch between a grinding disc, wire brush, or polishing pad depending on your project.

Cut-Off Grinder Overview

What Is a Cut-Off Grinder

You use a cut-off grinder when you need precise, straight cuts in metal, tile, or other tough materials. This tool looks similar to an angle grinder, but it focuses only on cutting tasks. The cutting accessory sits at a 90° angle to the driveshaft, which helps you make accurate cuts. You can operate most cut-off grinders with one hand because they are smaller and lighter than angle grinders. The lower horsepower, usually around 1 hp, makes them ideal for delicate jobs and tight spaces.

Here is a table that compares the defining characteristics of a cut-off grinder and an angle grinder:

Characteristic | Cut-Off Grinder | Angle Grinder |

Primary Function | Cutting tasks only | Cutting, grinding, polishing, sanding, shaping |

Cutting Accessory | 90° angle for precise cuts | Angled head for variable cutting angles |

Size & Weight | Small, light, portable | Larger, two-handed operation |

Power (Horsepower) | Lower (~1 hp) | Higher (3 to 7 hp) |

Control & Accuracy | Improved control, delicate cuts | Less precise, more powerful |

Application Scope | Confined spaces, small fabrication | Heavy-duty, versatile applications |

Maintenance & Cost | More expensive, higher maintenance | Less costly, lower maintenance |

Tip: You should choose a cut-off grinder when you need to work in tight corners or require extra control for small metal fabrication jobs.

Uses of Cut-Off Grinders

You will find cut-off grinders in professional workshops and construction sites. These tools excel at cutting tile, metal, and other hard materials. You can use them for tasks such as:

Cutting tile for flooring or wall installations

Sizing sheet metal for fabrication projects

Cutting stone for landscaping or masonry work

Removing welds for refabrication

Cutting rebar and structural steel in construction

Pipeline work and maintenance

Industry reports show that cut-off grinders are most often used for cutting metals like steel and rebar. You also see high demand for cutting tile in both residential and commercial projects. The automotive and aerospace sectors rely on these tools for metal processing and maintenance. When you select the right disc and follow safety guidelines, you achieve clean, accurate cuts in a variety of materials. You can also use cut-off grinders for cutting stone, which is common in landscaping and building projects.

Note: Always match the wheel size and RPM rating to your tool for safe and effective cutting tile or metal.

Key Differences

Design Comparison

When you compare an angle grinder to a cut-off grinder, you notice several design differences right away:

An angle grinder uses a powerful motor, usually between 3 to 7 horsepower. A cut-off grinder has about 1 horsepower, which means less power but more control for delicate work.

You operate an angle grinder with both hands. This gives you stability for heavy-duty tasks. A cut-off grinder is lighter and smaller, so you can use it with one hand. This makes it easier to work in tight spaces.

The head of an angle grinder sits at an angle. This lets you adjust your cutting angle and apply more power. The cut-off grinder has a head set at a 90-degree angle to the driveshaft. This design helps you make straight, precise cuts.

You can attach many types of discs to an angle grinder, including a grinding disc, flap disc, or wire wheel. The cut-off grinder only uses cutting discs.

Angle grinders cost less and need less maintenance. Cut-off grinders are more expensive and require more care, but they offer better accuracy for fine cuts.

Tip: If you need a tool for heavy-duty jobs and flexibility, choose an angle grinder. For small, precise cuts in tight spots, a cut-off grinder works best.

Disc Types

The type of disc you use changes how each tool performs. Angle grinders accept a wide range of discs. You can use a grinding disc for smoothing metal, a flap disc for blending welds, or a cut-off wheel for slicing through steel. Some discs, like the Diablo Type 1/41, fit both angle grinders and cut-off grinders if they have the right arbor system.

Cut-off grinders focus on thin cut-off wheels, usually Type 1 (flat) or Type 27 (depressed center). These wheels are designed for fast, clean cuts with less material waste. Grinding wheels are thicker and not safe for use on cut-off grinders.

Here is a table that shows the main disc types and their uses:

Disc Type | Shape/Thickness | Main Use | Compatible Tool |

Type 1 Cut-Off Wheel | Flat, ultra-thin | Cutting only | Cut-off grinder, angle grinder (with proper arbor) |

Type 27 Cut-Off Wheel | Depressed center, thin | Flush cutting | Angle grinder |

Grinding Disc | Thick (1/8" to 1/4") | Grinding, blending | Angle grinder |

Flap Disc | Layered abrasive flaps | Smoothing, finishing | Angle grinder |

Wire Wheel/Brush | Wire bristles | Cleaning, rust removal | Angle grinder |

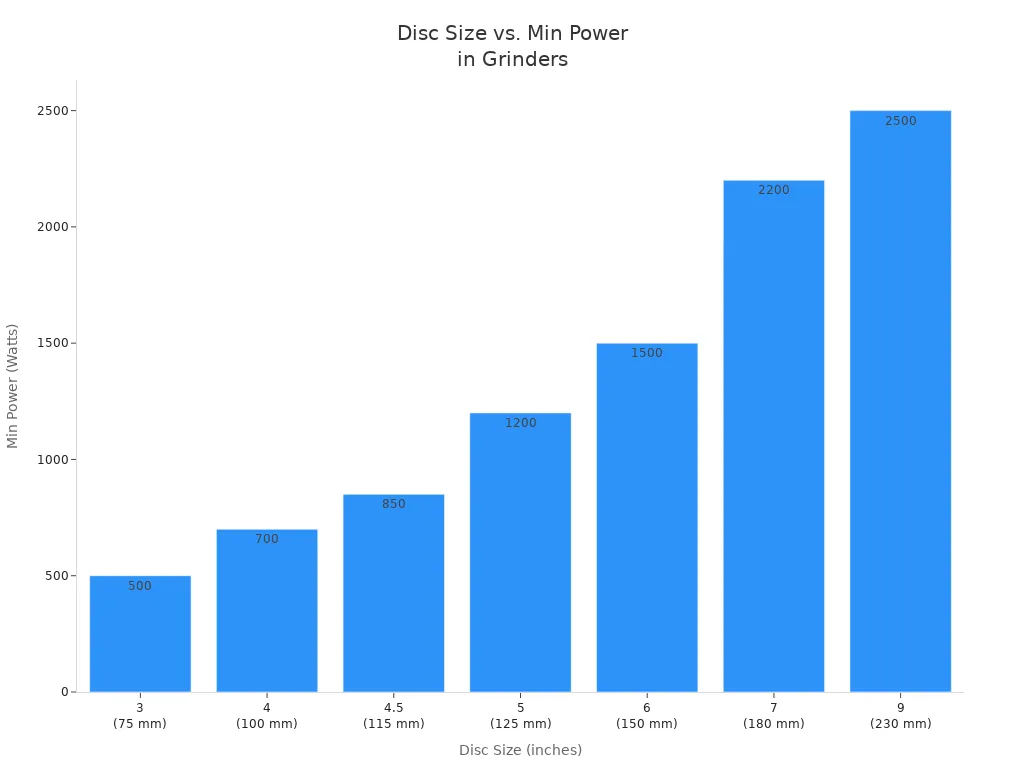

Disc size also matters. Smaller discs (3-4.5 inches) give you more control for detailed work. Medium discs (4.5-6 inches) balance power and maneuverability. Large discs (7-9 inches) cut deeper and handle tough jobs. The material of the disc—abrasive, diamond, or carbide—affects what you can cut and how long the disc lasts.

Note: Always match the disc size and type to your tool and task for safe, efficient results.

Versatility

You get much more versatility from an angle grinder than from a cut-off grinder. With an angle grinder, you can:

Cut, grind, sand, polish, and shape metal, wood, stone, and concrete.

Use a grinding disc, flap disc, wire brush, or cut-off wheel.

Switch between tasks quickly by changing attachments.

Handle heavy-duty jobs or delicate work, depending on the disc and speed.

A cordless angle grinder adds even more flexibility. You can move around your workspace without worrying about cords. This makes it perfect for outdoor projects or places without easy access to power.

A cut-off grinder is less versatile. You use it mainly for cutting. It excels at making straight, clean cuts in metal, tile, or stone, but you cannot use it for grinding, sanding, or polishing.

Task/Capability | Angle Grinder | Cut-off Grinder |

Cutting | Yes | Yes |

Grinding | Yes | No |

Sanding | Yes | No |

Polishing | Yes | No |

Shaping | Yes | No |

Deburring | Yes | No |

Carving | Yes | No |

Sharpening | Yes | No |

A cordless angle grinder can replace several specialized tools in your workshop, saving you money and space.

Safety Features

Both angle grinders and cut-off grinders come with important safety features. You will find a safety guard on each tool. This guard protects you from sparks, debris, and broken discs. Never remove or tamper with the guard. Doing so increases your risk of injury.

Angle grinders have two handles for a secure grip. This helps you control the tool, especially when using a cordless angle grinder for tough jobs. Cut-off grinders are lighter and often used with one hand, but you should always keep a firm grip.

Always use discs rated for your tool’s RPM. Using the wrong disc can cause it to shatter. Personal protective equipment, such as safety glasses and gloves, adds another layer of protection.

Always check the safety guard and handles before starting your cordless angle grinder. This simple step keeps you safe and improves your results.

Cutting Metal

Angle Grinder for Cutting Metal

You can use an angle grinder for cutting metal quickly and efficiently. This tool works best for heavy-duty jobs where speed matters more than precision. To get the best results and stay safe, follow these steps:

Gather your equipment: angle grinder, metal cutting blade, safety glasses, gloves, hearing protection, clamps, and a ruler or marker.

Prepare your workspace. Remove flammable items, ensure good ventilation, and keep a fire extinguisher nearby.

Mark your cutting line with a ruler or marker.

Secure the metal with clamps or a vise.

Attach the cutting disc correctly and adjust the safety guard.

Hold the grinder with both hands. Apply steady pressure and follow the marked line.

For straight cuts, move along the guideline. For curves, make several gentle passes.

Always wear your safety gear and let the blade cool between cuts.

Angle grinders have high horsepower (3 to 7 hp) and spin at over 6,000 rpm. This means you can remove material fast, making them ideal for tasks like cutting bolts or notching steel. However, you may notice less accuracy compared to specialized tools.

Tip: Never use a circular saw blade on your angle grinder. Always use discs rated for your tool.

Cut-Off Grinder for Cutting Metal

A cut-off grinder gives you more control and accuracy when cutting metal. You can operate it with one hand, making it perfect for tight spaces and delicate jobs. The tool uses a thin cut-off wheel and lower horsepower, so you get cleaner, finer cuts.

Feature | Cut-Off Grinder | Angle Grinder |

Accuracy | High | Moderate |

Speed | Slower | Faster |

Best For | Thin metals, small parts | Thick metals, quick jobs |

Handling | One-handed, precise | Two-handed, powerful |

You should use a cut-off grinder when you need to cut small pipes, sheet metal, or work in confined areas. The tool’s design helps you avoid mistakes and achieve a professional finish.

Choosing a Tool

When choosing between an angle grinder and a cut-off grinder for cutting metal, consider these factors:

Use an angle grinder for fast, rough cuts on thick or hard materials.

Choose a cut-off grinder for precise, clean cuts on thin metals or in tight spaces.

Think about the size of your project, the level of accuracy you need, and your workspace.

If you want a tool that can handle multiple tasks like grinding, sanding, or sharpening, an angle grinder offers more versatility. For jobs that demand accuracy and control, a cut-off grinder is the better choice.

Remember: Always match your tool and disc to the job for the safest and best results.

You now know the key differences between angle grinders and cut-off grinders. Angle grinders offer more power and versatility, handling grinding, sanding, and cutting tasks, while cut-off grinders excel at precise, straight cuts in tight spaces. Experts and users agree that matching the tool to your job improves safety and efficiency. Always consider your project needs, workspace, and comfort features before choosing. The best angle grinders can handle many tasks, but the right tool for your job makes all the difference.

FAQ

Can you use an angle grinder as a cut-off grinder?

You can use an angle grinder for cutting tasks if you attach a cut-off wheel. Always check the disc type and safety guard. Angle grinders offer more versatility, but cut-off grinders provide better control for straight cuts.

What materials can you cut with an angle grinder?

You can cut metal, tile, stone, and wood with an angle grinder. Choose the correct disc for each material. For example, use a diamond blade for tile and a cut-off wheel for metal.

Is an angle grinder safe for beginners?

Angle grinders are safe if you follow instructions and wear protective gear. Always check the safety guard and use both handles. Start with simple tasks and practice control before moving to tougher jobs.

How do you choose the right disc for your angle grinder?

Tip: Match the disc to your task.

Use a grinding disc for smoothing metal, a cut-off wheel for slicing, and a flap disc for finishing. Check the disc size and RPM rating to fit your angle grinder.

What maintenance does an angle grinder need?

Clean your angle grinder after each use. Inspect the disc and guard for damage. Lubricate moving parts and check the battery if you use a cordless angle grinder. Regular maintenance keeps your tool safe and efficient.