Key Takeaways

Identify your project needs first. Consider whether you need power for heavy tasks or precision for detailed work.

Choose the right disc size for your angle grinder. Smaller discs are better for control, while larger discs handle tougher materials.

Prioritize safety features. Look for tools with anti-kickback, paddle switches, and ergonomic designs to enhance comfort and reduce injury risk.

Compare corded and cordless models. Corded grinders offer unlimited power, while cordless models provide mobility for outdoor or tight spaces.

Read reviews and check brand reputation. User feedback can guide you to reliable tools that suit your specific projects.

Angle Grinder Basics

Common Uses

You might wonder why so many people rely on an angle grinder for their projects. This tool stands out because it handles a wide range of tasks. Here are some of the most common ways you can use angle grinders:

Cut through metal sheets, pipes, and rods in metalworking.

Smooth out welds and prepare surfaces for painting or finishing.

Tackle construction jobs like cutting ceramic tiles, concrete slabs, and bricks.

Remove rust or old paint from car parts and tools during automotive repairs.

Shape wood, strip paint, or remove rough spots in woodworking projects.

Handle home improvement jobs, such as sharpening tools or making custom repairs.

Take on creative projects, like making sculptures or decorative metalwork.

Tip: Always match the disc type and size to your specific project for the best results.

Types Available

When you look for an angle grinder in 2026, you will see several types. Each one fits different needs and work environments. Here’s a quick comparison:

Type | Key Advantages | Typical Uses |

Corded Electric | Unlimited runtime, strong power, lower cost | Construction, metal fabrication, welding |

Cordless Electric | Full mobility, lightweight, easy to set up | Remote sites, quick repairs, landscaping |

Pneumatic | Lightweight, runs continuously, safer in wet conditions | Automotive repair, shipyards, metal shops |

Corded angle grinders give you steady power for tough jobs. Cordless models let you move freely, which helps when you work in tight spaces or outdoors. Pneumatic grinders work well in places where electricity is risky or not available.

You can choose the right angle grinder by thinking about your projects and where you plan to use the tool. This way, you get the best mix of power, convenience, and safety.

Best Angle Grinder Features

Power Source: Corded or Cordless

You face a big choice right away: corded angle grinders or cordless angle grinders. Each type brings its own strengths and weaknesses to your project. If you want unlimited runtime and steady power, corded angle grinders fit best. They plug into an outlet and keep going as long as you need. You might find them lighter in hand, but the cord can get in your way or limit your movement.

Cordless angle grinders run on rechargeable batteries. They give you freedom to move, which helps when you work outside or in tight spots. You can set up quickly and avoid tripping over cords. However, battery life limits your working time—most cordless angle grinders last about 20 to 30 minutes per charge. You may also notice they cost more, especially if you need extra batteries.

Here’s a quick comparison to help you decide:

Feature | Corded Angle Grinder | Cordless Angle Grinder |

Power Source | Direct from outlet, unlimited use | Rechargeable batteries, limited runtime |

Mobility | Restricted by cord | Highly portable, no cords |

Performance | Consistent high torque and RPM | Strong, but may struggle with heavy jobs |

Cost | Lower upfront | Higher (tool + batteries + charger) |

Weight | Lighter, but cord drags | Slightly heavier, battery adds weight |

Best For | Workshops, long sessions | DIY, outdoor, remote work |

Tip: If you work in a shop or need to cut thick metal all day, corded angle grinders make sense. For quick jobs or repairs away from outlets, cordless angle grinders are a smart pick.

Motor Power and Speed

The heart of any angle grinder is its motor. You want enough power to handle your toughest tasks, but not so much that you lose control. For most home projects, a motor with at least 6 amps (about 800 watts) and 10,000 RPM works well. If you plan to tackle heavy fabrication or professional welding, look for at least 6.7 amps and up to 11,800 RPM.

Modern angle grinders often feature brushless motors. These motors last longer and need less maintenance than brushed motors. They also run cooler and use energy more efficiently, which means you get more work done per charge if you choose a cordless model.

Variable speed control is another handy feature. You can slow things down for polishing or crank up the speed for cutting metal. Most grinders let you adjust from 2,800 to 12,000 RPM. High speeds help you cut and grind quickly, while lower speeds protect delicate surfaces.

Traditional angle grinders: 9,000–12,000 RPM

High-performance models: Up to 12,500 RPM

Variable speed: 2,800–11,000 RPM

Note: Brushless motors can last up to 50% longer than brushed motors and require less upkeep.

Disc Size Selection

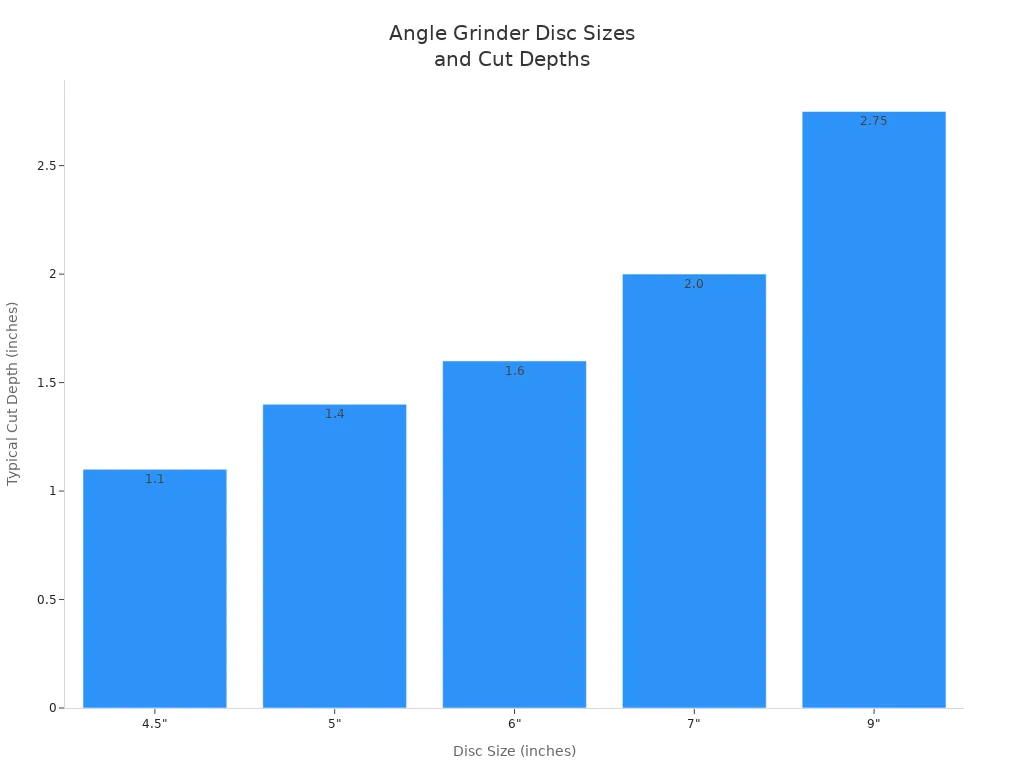

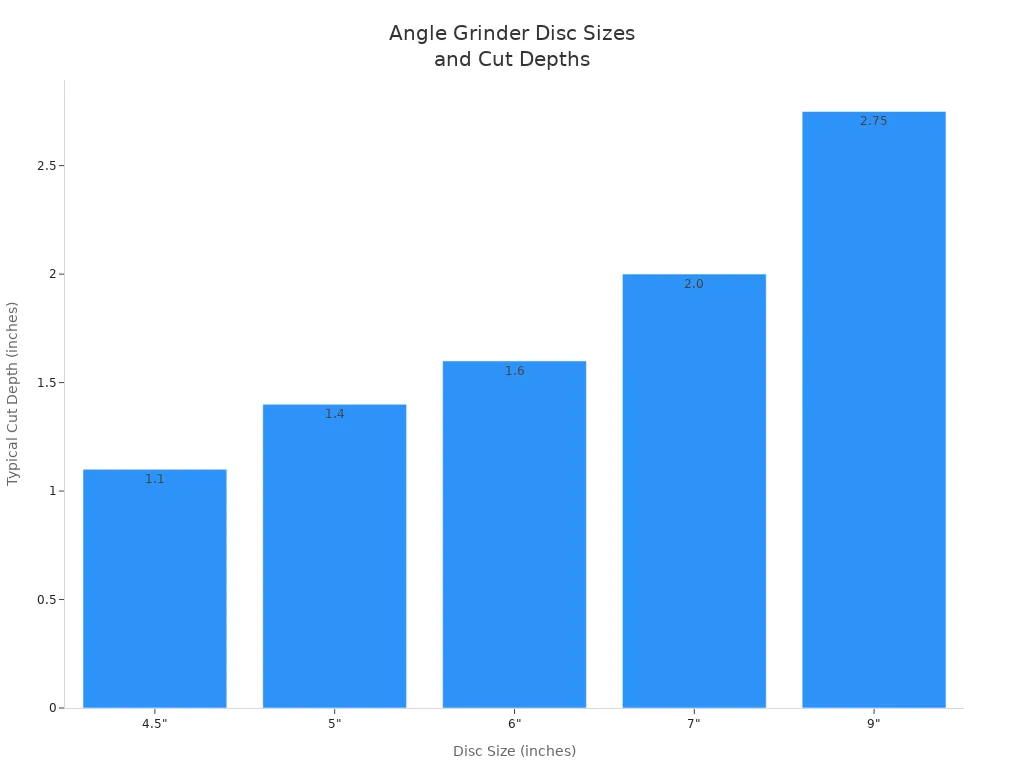

Disc size matters more than you might think. The diameter of your cutting disc or grinding disc decides how deep you can cut and what materials you can handle. If you need to select the right grinding disc, start by thinking about your project’s needs.

Here’s a breakdown of common disc sizes and what they do best:

Disc Size | Typical Cut Depth | Best Suited For | Key Advantages |

4.5" | ~1.1" | Small jobs, detail work | Lightest, easy to control, low cost |

5" | ~1.3–1.5" | Everyday projects | Good mix of depth and control |

6" | ~1.6" | Medium-thickness steel | Quicker progress, modest weight |

7" | ~2.0" | Heavy-duty cuts | Depth, speed, handles kickback |

9" | ~2.7–2.8" | Thick steel/stone, industrial | Maximum capacity, for experts |

4.5" discs work well for home repairs and car bodywork.

5" discs are versatile for both homeowners and pros.

6" discs balance speed and weight for quick cuts.

7" discs handle heavy-duty jobs like concrete and steel.

9" discs suit industrial work and experienced users.

Callout: Always match your disc size to your grinder and your project. Bigger isn’t always better—large discs cut deeper but need more skill and control.

Safety and Comfort

Safety should always come first when you use an angle grinder. Look for features like anti-kickback and torque control, which stop the tool if it snags or binds. Dead-man and paddle switches cut power if you lose your grip, preventing accidents. Soft start and variable speed features help you ease into your work and avoid sudden jolts.

Safety Feature | Description |

Anti-kickback & torque control | Detects sudden torque spikes, cuts power instantly |

Dead-man & paddle switches | Stops the motor when grip is lost |

Soft start & variable speed | Reduces initial torque, lets you match RPM to material |

Comfort matters, too. Many angle grinders now include anti-vibration handles and ergonomic grips. These features reduce hand strain and help you control the tool, especially during long sessions. Some handles cut vibration by up to 60%, which lowers your risk of hand and arm injuries.

Anti-vibration handles make the tool easier to hold and guide.

Ergonomic designs spread out the force, so your hand, wrist, and arm stay comfortable.

Rubberized grips and advanced discs also cut down on noise, making your workspace safer for your ears.

Safety Tip: Always wear hearing protection and gloves when you use an angle grinder. Even the best angle grinder can be dangerous if you skip safety gear.

By focusing on these features—power source, motor strength, disc size, and safety—you can pick the angle grinder that fits your project and keeps you working safely and comfortably.

Choosing the Right Angle Grinder

Match Grinder to Project Needs

You want the right angle grinder for your projects, not just any tool. Start by thinking about what you need most: power or precision. If you plan to cut thick steel beams or concrete, you need a grinder with higher power. For detailed work, like shaping metal edges or working in tight corners, precision matters more. Smaller angle grinders give you better control and fit into small spaces. Larger models handle demanding jobs but can feel heavy and harder to manage.

Here’s a quick way to match the right angle grinder to your project:

Light tasks (like trimming thin metal or small repairs): Choose a 4.5-inch or 5-inch grinder with 500-750 watts.

Medium projects (such as cutting medium metal pipes or tiles): Go for a 6-inch grinder with 750-1,200 watts.

Heavy-duty work (cutting thick steel, concrete, or stone): Pick a 7-inch or 9-inch grinder with 1,200-2,000 watts.

You can also use this table to help decide:

Criteria | Description |

Disc Size | Determines cut depth and surface area. 4.5-inch for home use, larger sizes for heavy tasks. |

Safety Features | Look for adjustable guards, safety switches, and anti-vibration handles. |

Ergonomics and Weight | Lighter models are easier to handle. Heavier models offer more stability for big projects. |

Power Requirements | Small grinders (500-750 watts) for light tasks, large grinders (1,200-2,000 watts) for tough jobs. |

Budget Considerations | Entry-level models cost less but may lack features. High-end models offer more durability. |

Tip: If you work overhead or in remote spots, cordless angle grinders make your job easier. Lighter tools with ergonomic handles help you work longer without fatigue.

Budget and Value

You want the best angle grinder for your money, so let’s look at what you get at each price point. Entry-level angle grinders cost between $30 and $75. These work well for simple home improvement projects or occasional repairs. Mid-range models, priced from $75 to $150, offer more power, better safety features, and longer life. Professional-grade grinders start at $150 and can go over $300. These deliver top performance and durability for daily, heavy-duty use.

Here’s a quick price guide:

Grinder Type | Price Range |

Entry-level | $30 - $75 |

Mid-range | $75 - $150 |

Professional-grade | $150 - $300+ |

When you compare value, look for features that matter most for your projects. A larger disc diameter gives you deeper cuts. Higher wattage and variable speed let you tackle tough materials and switch between tasks. Corded models work well in a shop, while cordless grinders give you freedom outdoors. Brushless motors last longer and need less maintenance. For safety, check for slow start, anti-kickback, and paddle switches.

Feature | Description |

Disc Diameter | Larger discs cut deeper; sizes range from 4" to 9". |

Wattage and Speed | More watts for tough jobs; variable speed for different materials. |

Power Source | Corded for steady power; cordless for mobility; brushless motors for durability. |

Protection Features | Slow start, anti-kickback, restart protection, paddle switch. |

Note: Sometimes, paying a bit more up front saves you money in the long run. A durable angle grinder with good safety features can last for years and handle all your projects.

Brand and Reviews

You want a tool you can trust, so brand reputation matters. Well-known brands often offer better warranties, more reliable customer service, and a wider range of accessories. Before you buy, check online reviews and ratings. See what other users say about performance, comfort, and durability. Look for feedback from people who use their angle grinders for similar projects.

Here’s how you can use reviews to make a smart choice:

Read both positive and negative reviews to spot common issues.

Check if users mention the tool’s weight, balance, and ease of use.

Look for comments about battery life if you want a cordless model.

See if reviewers mention safety features and how well they work.

Callout: Your experience level matters, too. If you’re new to angle grinders, start with a smaller, lighter model with strong safety features. If you’re a pro, you might want a larger, more powerful grinder for big projects.

Choosing the right angle grinder means matching the tool to your project needs, budget, and skill level. Think about where you’ll use it, how much power you need, and which features matter most for your safety and comfort. With the right choice, you’ll tackle all your projects with confidence.

You can pick the best angle grinder for your project by following a few simple steps:

Decide how much power you need for your tasks.

Choose the right disc size for your materials.

Look for safety features like adjustable guards and paddle switches.

Check for extra features and durability.

Compare prices and read reviews.

Remember, the right tool keeps you safe and makes your work easier. Take a moment to compare your options and choose with confidence!

Common Mistake | How to Avoid |

Using the wrong disc | Match disc size to your project |

Ignoring safety features | Always check for safety functions |

FAQ

What size angle grinder should I use for home projects?

You should pick a 4.5-inch or 5-inch angle grinder for most home tasks. These sizes give you good control and work well for cutting, grinding, and polishing.

Can I use an angle grinder to cut wood?

Yes, you can use an angle grinder to cut wood, but you need the right disc. Always use a wood-cutting disc and wear safety gear to protect yourself from flying debris.

How do I maintain my angle grinder?

You should clean your angle grinder after each use. Check the disc for wear, tighten all parts, and store it in a dry place. Regular care helps your tool last longer.

Are cordless angle grinders as powerful as corded ones?

Cordless angle grinders have improved a lot. They now offer strong performance for most jobs. For heavy-duty work, a corded model still gives you more power and longer run time.

What safety gear should I wear when using an angle grinder?

You should always wear safety glasses, gloves, and hearing protection. A dust mask and long sleeves help protect you from sparks and dust.