In electronic devices and power systems, capacitors—especially large electrolytic types—are essential energy storage components. They usually operate silently, stabilizing circuits. Yet, under certain conditions, these seemingly harmless elements can turn into dangerous "bombs," exploding violently. Such events not only damage equipment but also pose serious risks to personal safety—just like the recent incident involving capacitor explosions in over 40 TTI cleaning machines. So, what causes these explosions, and how dangerous are they?

I. The Root Cause: Loss of Internal Pressure Control

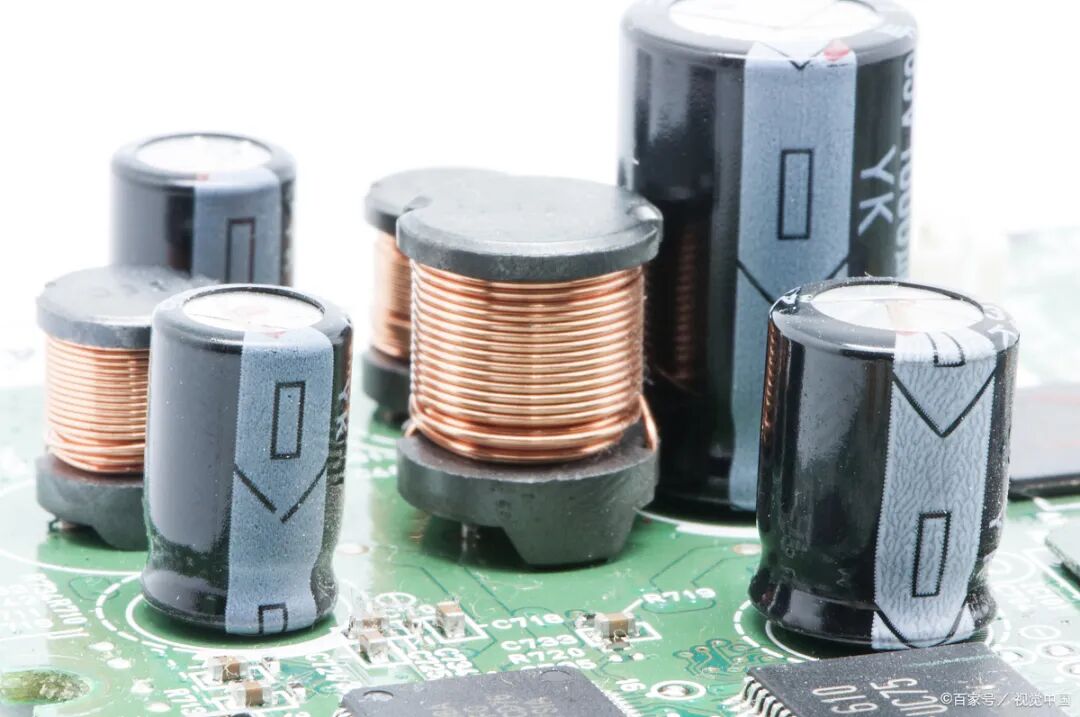

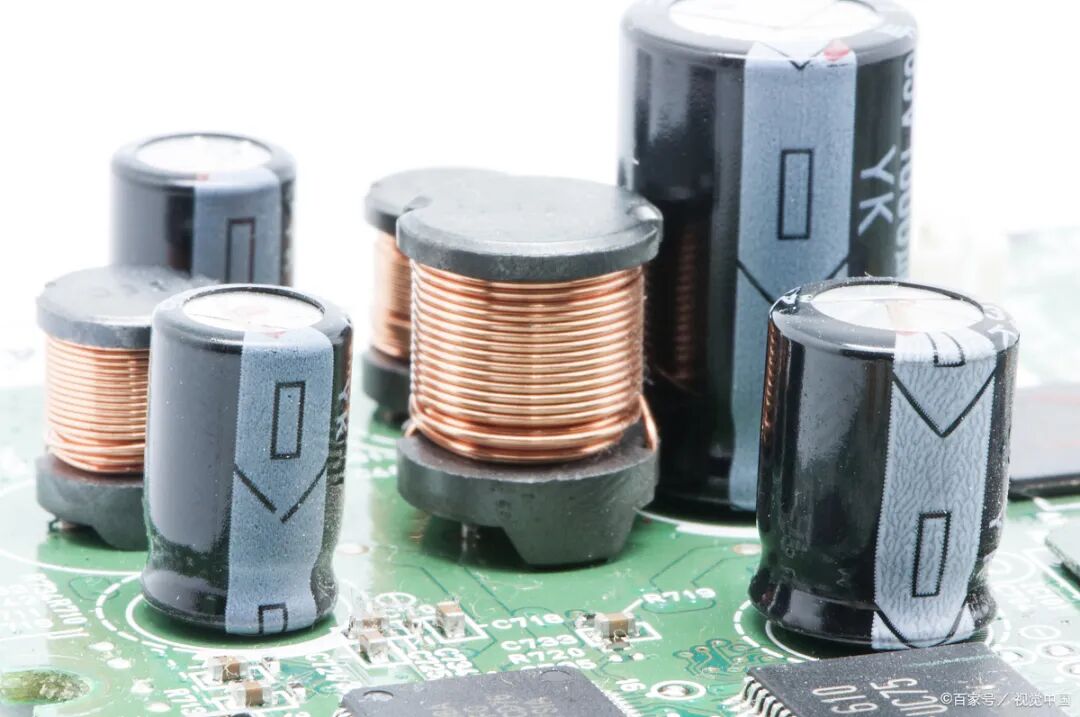

To understand why capacitors explode, we must first look at their structure. Take the common aluminum electrolytic capacitor as an example:

Internal Structure: It contains paper dielectric soaked in electrolyte, sandwiched between two aluminum foils (anode and cathode), all sealed in an aluminum casing.

Working Principle: When charged, an ultra-thin insulating oxide layer forms on the anode foil, which is key to storing electrical energy.

Trigger Point for Explosion: The sealed electrolyte boils when heated, generating gas that rapidly increases internal pressure until the casing bursts—similar to a pressure cooker with blocked safety valves.

II. Specific Causes of Pressure Buildup (Triggers for Explosion)

Several common conditions can cause overheating, gas generation, and eventual explosion:

Overvoltage – The Most Common Cause: When voltage exceeds the capacitor’s rated value, the dielectric oxide layer breaks down, causing a short circuit. High short-circuit current instantly heats the electrolyte, producing gases (mainly hydrogen) and rapidly increasing pressure until the casing ruptures.

Reverse Polarity: Electrolytic capacitors are polarized. If connected in reverse, internal chemical reactions are disrupted, leading to high current flow, rapid heat and gas generation, and potential explosion—especially common during maintenance or replacement.

Overheating: Capacitor lifespan and performance are highly sensitive to temperature. High ambient temperature or excessive ripple current can cause rapid temperature rise.

Aging and Failure: Over time, the electrolyte gradually dries up, increasing equivalent series resistance (ESR). This leads to higher power loss and heat under the same current, accelerating failure.

Manufacturing Defects: Poor sealing, contaminated electrolyte, or internal burrs can cause premature failure even under normal operating conditions.

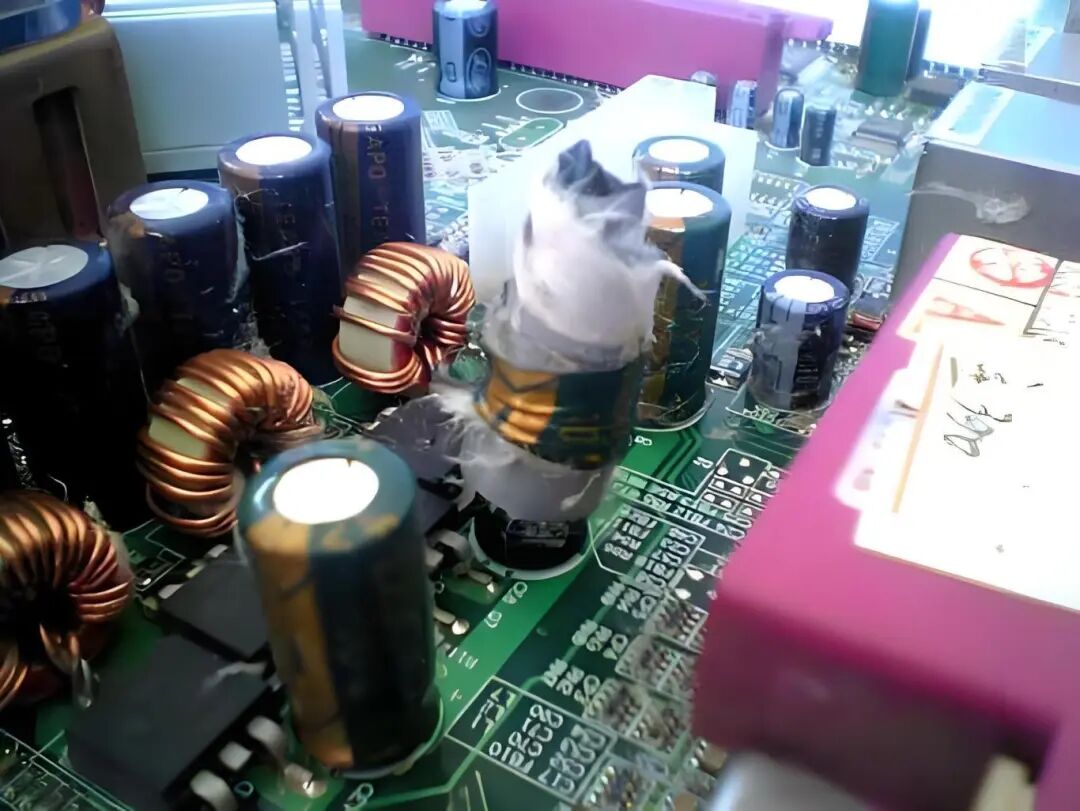

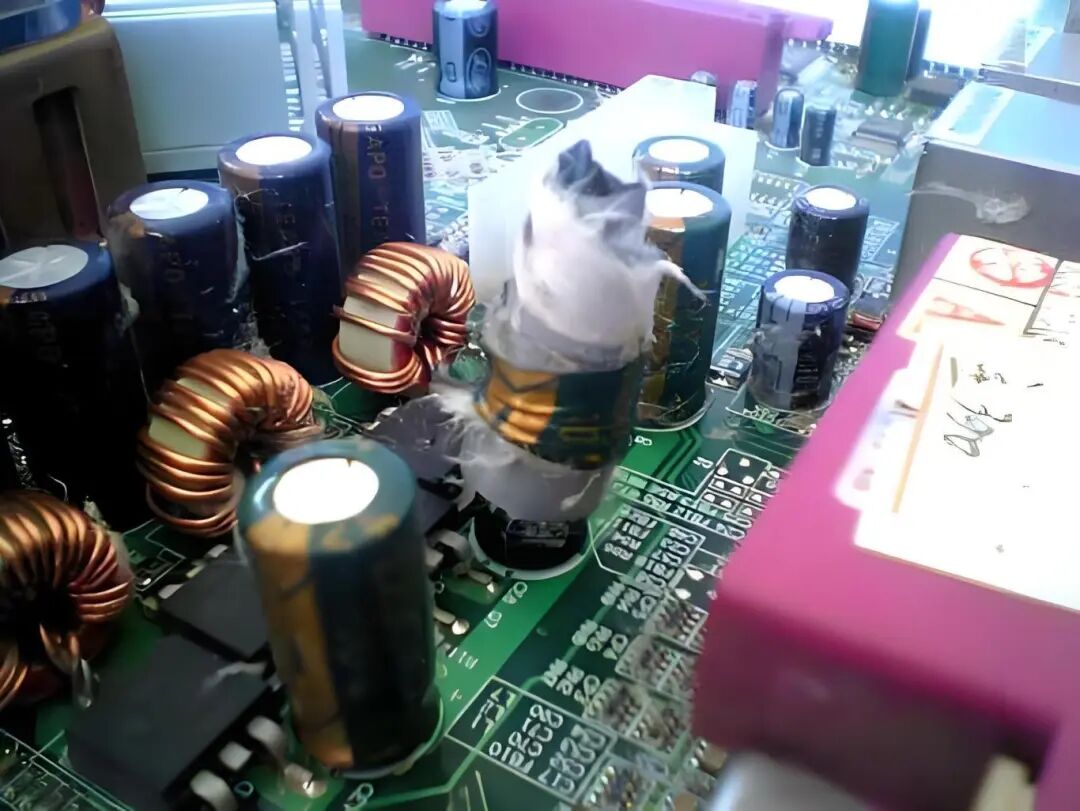

III. Hidden Dangers of Capacitor Explosions

A capacitor explosion is more than just a "pop"—it brings multiple hazards:

Physical Blast Damage: The metal casing can fragment into high-speed shrapnel capable of penetrating fragile objects and causing serious injury.

Fire Hazard: Sparks from the explosion may ignite flammable gases (e.g., hydrogen) and other materials inside the device.

Chemical Corrosion: Electrolyte is often highly corrosive and toxic. When ejected, it can irreversibly damage circuit boards and components, or cause severe chemical burns to skin and eyes.

Secondary Equipment Damage: Exploding capacitors can destroy the entire circuit board, with shrapnel and electrolyte shorting other critical components, leading to complete device failure and costly repairs.

Conclusion

At its core, a large capacitor explosion results from a loss of thermal and pressure control triggered by overvoltage, reverse polarity, overheating, or other factors. It is not merely a component failure—it’s a complex safety event involving physical explosion, chemical corrosion, and fire risk.

Yet, the most fundamental solution may lie in rethinking the design itself: minimizing or eliminating the need for large electrolytic capacitors. With rapid technological advances, "capacitor-free" solutions are becoming a key trend in power electronics, driving the development of power supplies that are more efficient, compact, and safe.