A straight grinder is a powerful and versatile tool used in various industries, from metalworking to woodworking. Its design allows it to be used for tasks that require precision, making it ideal for grinding, sanding, polishing, and cutting. Understanding the different sizes, types, and uses of a straight grinder is essential for selecting the right tool for your projects. This guide will walk you through everything you need to know.

What is a Straight Grinder?

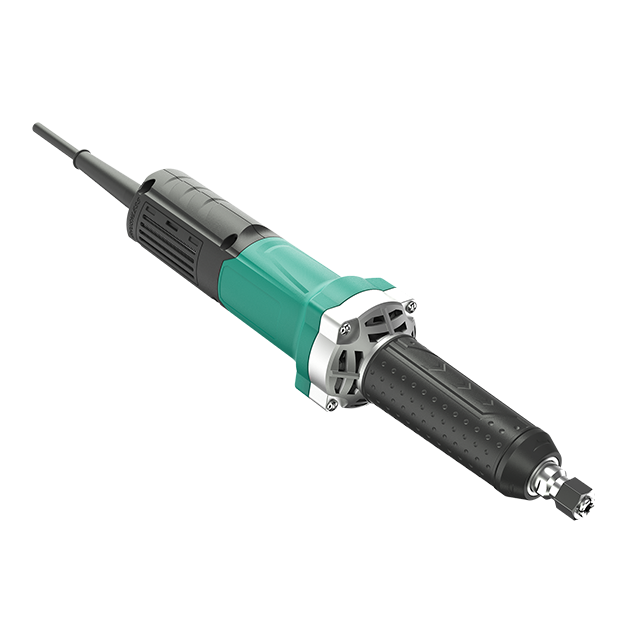

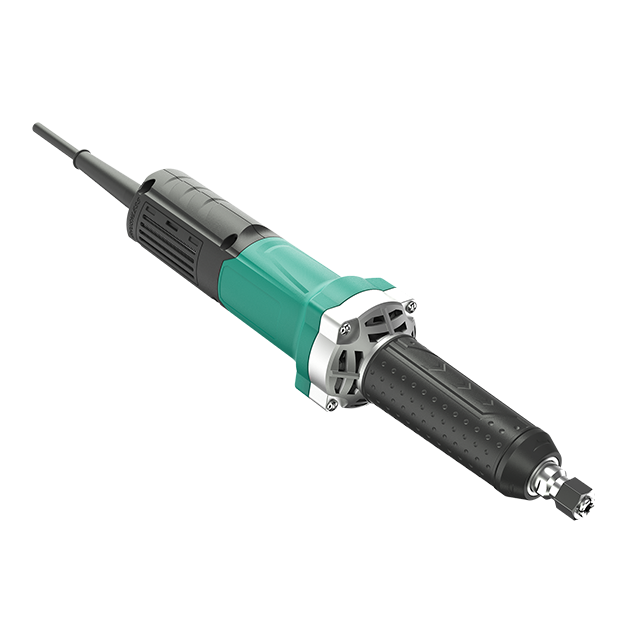

Definition of a Straight Grinder

A straight grinder is a high-speed, handheld power tool that rotates at high RPM (revolutions per minute). This rotation allows the tool to perform tasks such as grinding, sanding, and polishing various materials. Unlike the more common angle grinders, the straight grinder has a straight body and a rotating spindle. This design offers better control for precision tasks and allows it to work in tight spaces where an angle grinder might not fit.

Key Components of a Straight Grinder

To get the most out of a straight grinder, it’s essential to understand its key parts:

Motor: Powers the tool, rotating the spindle and driving attachments at high speed.

Collet and Spindle: The collet secures the attachment, while the spindle allows it to rotate at high RPM.

Handle: The handle is ergonomically designed to provide a firm grip, making the tool easier to control.

Safety Features: Modern straight grinders come equipped with features like overload protection, soft start mechanisms, and restart protection to ensure safe operation.

How Does a Straight Grinder Work?

A straight grinder operates by rotating its spindle and attachment at high speeds. The motor’s power drives the rotation, which allows the attachment to remove material from the workpiece. Depending on the task, different attachments can be used for grinding, sanding, polishing, or cutting. The speed of the grinder can be adjusted for different applications, ensuring that the tool delivers the right amount of power for the job at hand.

Uses of a Straight Grinder

Metalworking Applications

One of the primary uses of a straight grinder is in metalworking. It’s an essential tool for grinding and deburring metal surfaces. Common tasks include smoothing out rough weld seams, removing rust, and polishing metal parts. Specialized attachments like carbide burrs and grinding wheels make it easy to achieve smooth, clean, and polished metal surfaces. For industrial metalwork, straight grinders are used for tasks that require both precision and power.

Woodworking Applications

While straight grinders are most commonly associated with metalworking, they are also incredibly useful in woodworking. By attaching a sanding disc or drum, a straight grinder can smooth rough wood surfaces, finish intricate wood carvings, and even polish wooden surfaces to a glossy shine. The precision and control offered by the straight body of the grinder allow users to work on detailed wood projects effectively.

Automotive and Construction Uses

In the automotive and construction industries, straight grinders are used to smooth out welds, remove rust from car parts, and clean metal surfaces. In construction, they’re used to prepare surfaces before painting or applying coatings. The tool's precision makes it ideal for tasks that require careful handling, such as polishing or sanding metal in automotive repairs or large-scale construction projects.

Other Applications

Straight grinders are not limited to just metal and wood. They’re also used for DIY projects, jewelry making, and general maintenance tasks around the home. Whether you're tackling minor repairs or detailed projects, a straight grinder can be a useful addition to your toolkit.

Sizes of Straight Grinders

Small Size Straight Grinders

Small straight grinders are typically lightweight, weighing under 1.5 lbs. These grinders are perfect for tasks that require high precision and control. With a small body and a high-speed motor, they are ideal for polishing delicate materials, sanding intricate details, and working in tight spaces. The lightweight design makes them easy to handle for extended periods, which is particularly useful for detailed tasks in metalworking and woodworking.

Medium Size Straight Grinders

Medium-sized straight grinders weigh between 1.5 to 3 lbs. These grinders offer a good balance between power and portability, making them versatile tools for a range of tasks. They are used for general-purpose grinding, sanding, and polishing in metalworking, automotive repairs, and woodworking. They provide a higher level of performance compared to smaller models while still maintaining a manageable weight for ease of use.

Heavy-Duty Straight Grinders

Heavy-duty straight grinders are built for tough jobs. They typically weigh over 3 lbs and are designed to handle demanding tasks like heavy grinding and extended use. These models offer higher torque and are perfect for industrial applications where high performance and durability are essential. They are ideal for professionals who require reliable, powerful tools for large-scale metalworking or construction projects.

Types of Straight Grinders

Pneumatic (Air-Powered) Straight Grinders

Pneumatic straight grinders are powered by compressed air, providing high torque for tough tasks. These grinders are commonly used in industrial environments where continuous operation is needed. The key advantage of pneumatic grinders is their ability to run continuously without overheating. However, they require an air compressor, which can limit mobility and may not be ideal for smaller, portable work environments.

Electric Straight Grinders

Electric straight grinders are more commonly used for light to medium tasks, including those found in home workshops and automotive repair shops. These grinders are powered by electricity, which makes them convenient to use in various locations without requiring an air compressor. They are often lighter than pneumatic models, making them easier to handle for smaller projects. However, they may not offer the same high torque as pneumatic models, making them less suitable for heavy-duty tasks.

Cordless Straight Grinders

Cordless straight grinders operate on rechargeable batteries, providing ultimate mobility. These grinders are ideal for work in locations without electrical outlets, such as outdoor projects or remote sites. While they are highly portable, the downside is that their battery life may be limited, and they might not offer as much power as electric or pneumatic grinders. However, advancements in battery technology are improving their performance and making them more viable for various tasks.

Brushless Motor Straight Grinders

Brushless motor straight grinders use advanced motor technology that eliminates the brushes in traditional motors. This provides several advantages: increased efficiency, longer lifespan, and less maintenance. Brushless motors are especially effective in straight grinders, as they provide more consistent performance, especially under load. These grinders are perfect for tasks that demand continuous operation and reliability.

Choosing the Right Straight Grinder for Your Task

Factors to Consider When Choosing a Straight Grinder

Material Type: Different materials such as metal, wood, and plastic may require different attachments, speeds, and grinder types. Always consider the material before choosing a grinder.

Power Source: Consider whether you need a pneumatic, electric, or cordless model. Pneumatic grinders are ideal for heavy-duty tasks, while electric grinders are more portable and versatile for general use. Cordless models are best for mobility and convenience.

Grinder Size: Choose a smaller model for precision tasks and a larger, more powerful model for heavy-duty applications. Ensure the size and weight match the type of work you will be doing.

Attachments and Accessories

A wide variety of attachments are available for straight grinders. Some common ones include:

Grinding Wheels: For heavy-duty grinding tasks like deburring or shaping.

Sanding Discs: Ideal for smoothing surfaces and sanding wood or metal.

Polishing Pads: Used for creating a shiny, smooth finish on metal, wood, or other materials.

Conclusion

A straight grinder is a versatile and efficient tool for tasks involving metal, wood, and plastic. Choosing the right model, size, and attachment ensures top performance. For durable, high-quality straight grinders, consider HOPRIO products. They offer reliable models with excellent features tailored to meet various professional and DIY needs, ensuring precision and longevity for every job.

FAQ

Q: What are the main differences between pneumatic and electric straight grinders?

A: Pneumatic grinders are air-powered and ideal for heavy-duty tasks, while electric grinders are more portable and suitable for lighter work.

Q: How do I know what size straight grinder to choose?

A: Choose a smaller grinder for precision work and a larger one for more demanding tasks like grinding or cutting tough materials.

Q: Can I use a straight grinder for polishing metal?

A: Yes, straight grinders are excellent for polishing metal when used with the appropriate attachment, such as a polishing pad or abrasive wheel.

Q: What type of attachments should I use with a straight grinder for woodwork?

A: For woodwork, use sanding discs or sanding drums for smooth finishing, and carbide burrs for detailed carving.