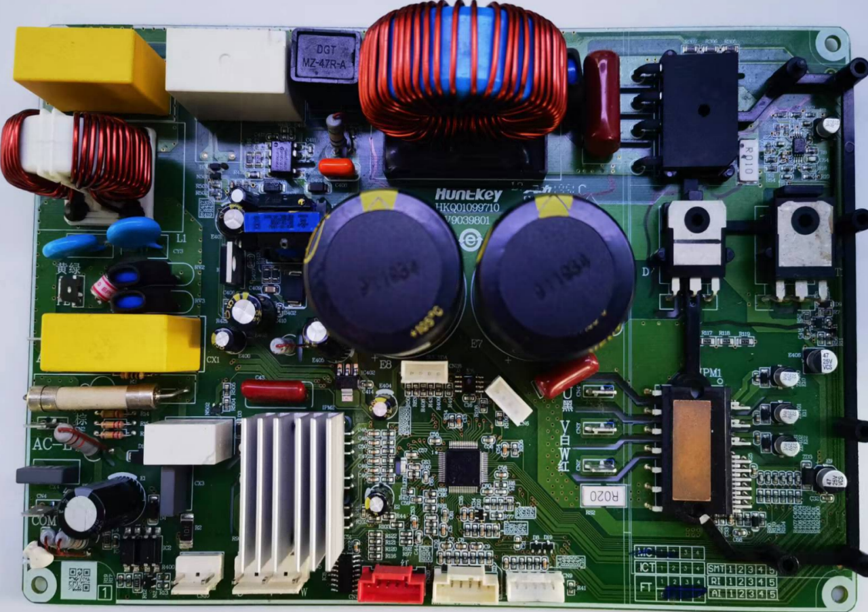

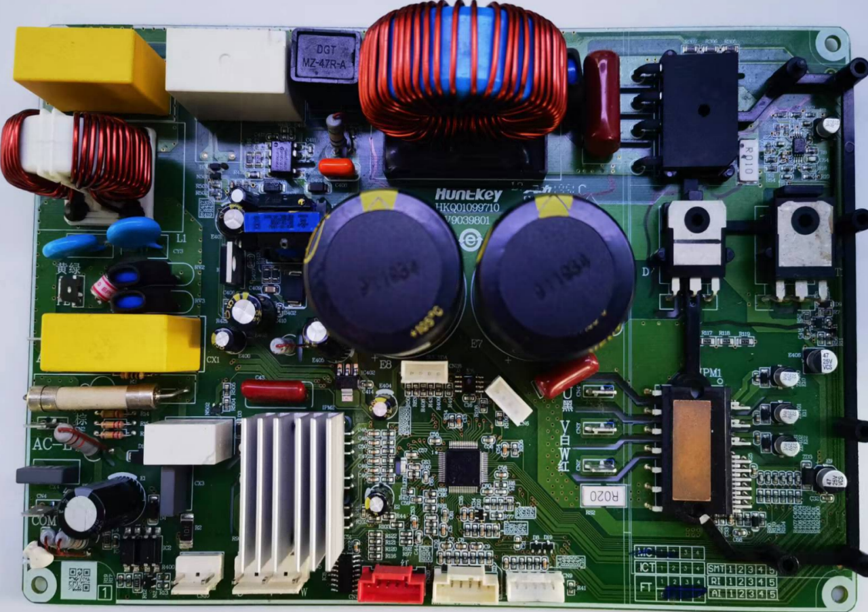

In recent years, with the widespread adoption of variable frequency drive technology, incidents involving large capacitor explosions have occurred frequently, becoming a safety hazard that many industries can no longer ignore. Large electrolytic capacitors, as key components in traditional variable frequency systems, are not only bulky and prone to failure, but also carry the risk of explosion due to overvoltage, overheating, or internal defects, posing serious threats to both personnel safety and equipment operation.

I. Traditional Challenges and Risks of Large Capacitor Solutions

Conventional variable frequency drive systems heavily rely on large electrolytic capacitors, which come with inherent drawbacks:

·Risk of Explosion and Failure: Electrolytic capacitors are prone to aging, bulging, and even explosion after prolonged use, especially under overvoltage or overheating conditions.

·Size and Cost Issues: The large size of capacitors leads to bulky overall designs and requires additional PFC circuits, increasing system complexity and cost.

·Low Energy Efficiency: Typically, power factor remains low (≈0.6), reducing grid-side efficiency and increasing energy consumption.

·Limited Overload Capacity: The charge-discharge characteristics of capacitors restrict the system's instantaneous overload capability.

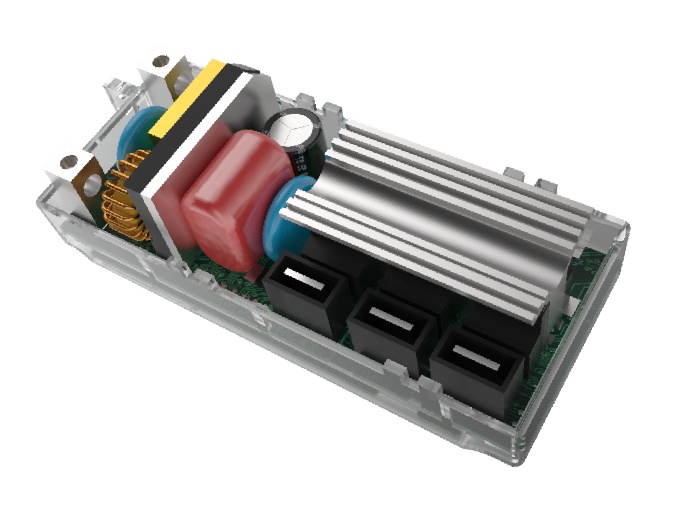

II. HOPRIO Capacitor-Free Solution: Reimagining Drive Systems Through Algorithm Innovation

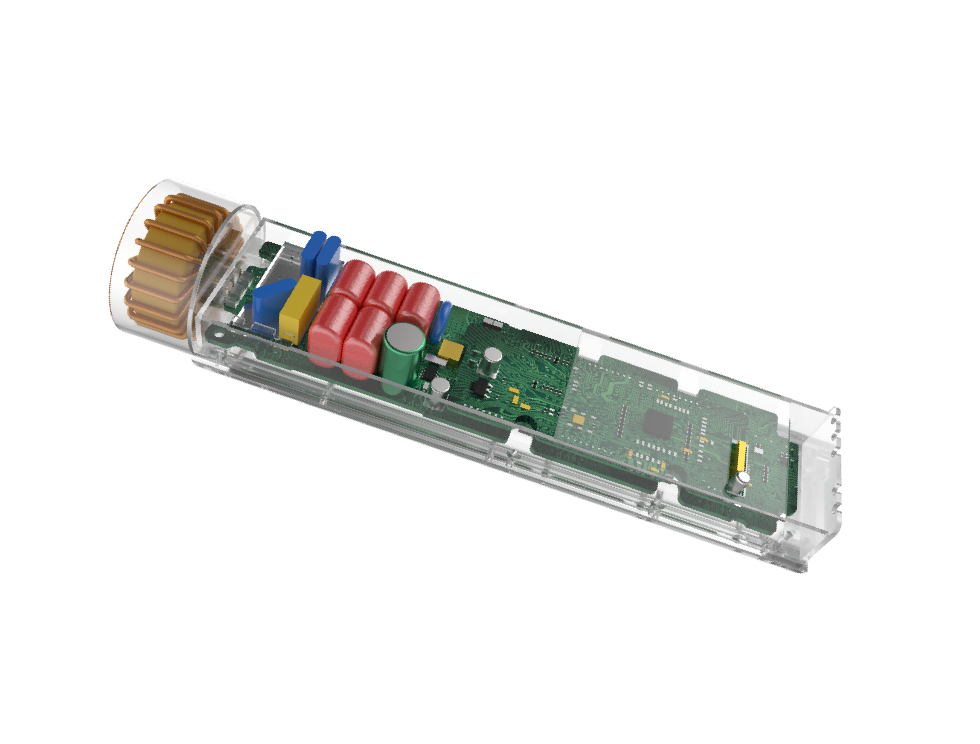

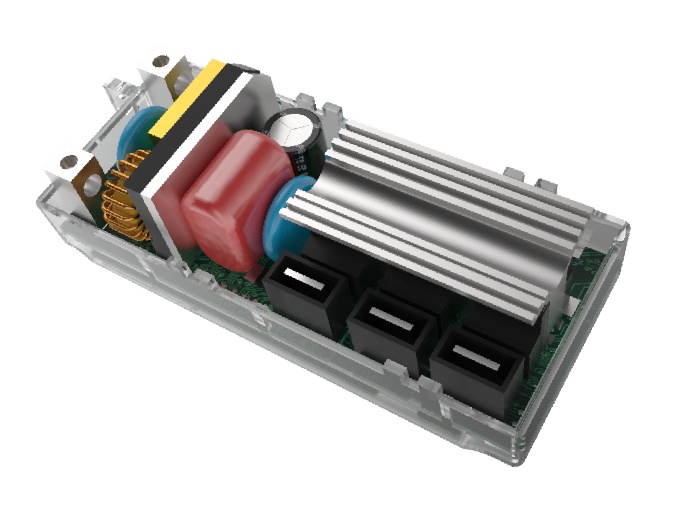

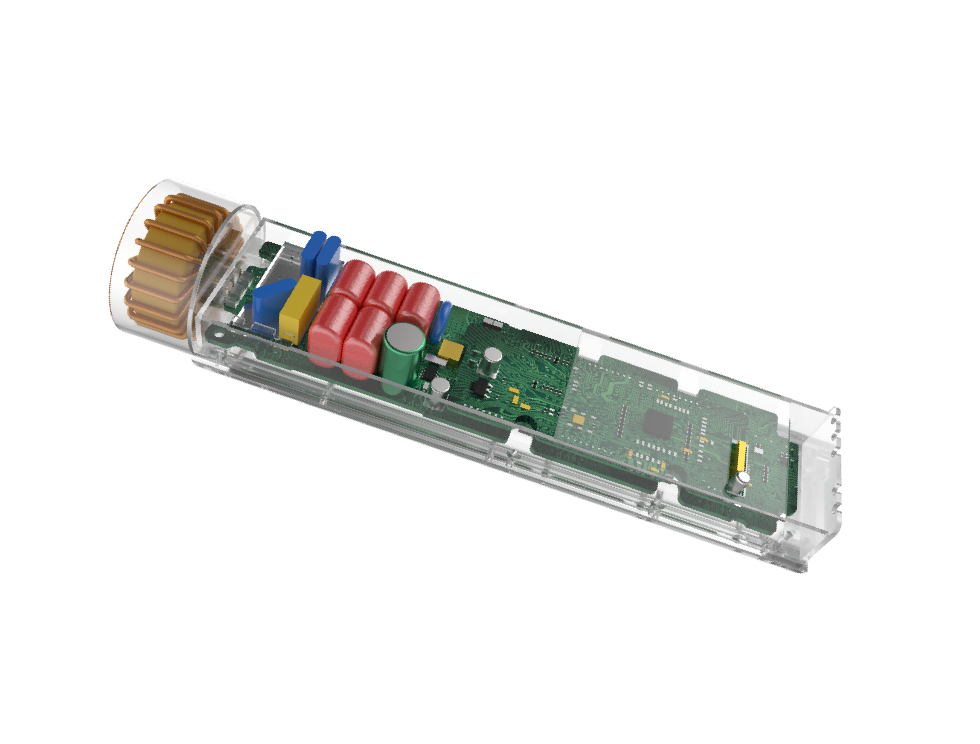

Leveraging its deep R&D expertise in permanent magnet motors and underlying frequency control systems, HOPRIO has completely eliminated electrolytic capacitors through three core technologies—intelligent variable frequency control, high-efficiency energy-saving drives, and integrated system design—achieving a more compact, efficient, and safe system:

·Compact Design: Removal of capacitors and PFC circuits makes the system structure more streamlined, ideal for high-density installation scenarios.

·High Power Factor (≥0.9): Real-time algorithm-based control of voltage and current phase enables efficient power use without hardware compensation.

·Strong Overload Capacity: Intelligent control algorithms support instant overload operation, offering faster response and higher reliability.

·Drastically Reduced Failure Rate: The absence of capacitors eliminates failures caused by aging or bursting, significantly extending system lifespan.

·Higher Motor Design Complexity with Clear Benefits: Though placing greater demands on motor design and control algorithms, the overall system achieves leaps in efficiency, reliability, and integration.

III. The Deep Expertise Behind the Technology: How Huapin Achieved "Capacitor-Free"

Removing capacitors is not a simple "subtraction" but a highly complex systems engineering effort. HOPRIO success stems from long-term investment and breakthroughs in foundational technologies:

·Advanced Algorithm Library: Self-developed variable frequency control algorithms precisely manage power flow in real time, replacing the "energy buffering" role of capacitors and enabling stable energy management without them.

·Deep Motor-Drive Co-design: Overcame the high demands of capacitor-free operation on motor design (e.g., back-EMF waveform, inductance parameters) by optimizing permanent magnet motor design for seamless integration with frequency drives.

·System-Level Problem Solving: Addressed associated challenges such as high-speed motor vibration, magnet demagnetization, and gear lifespan, ultimately developing a fully independent and technologically leading integrated drive system.

HOPRIO capacitor-free solution not only addresses the specific risk of capacitor explosions but also represents the evolution of variable frequency drive technology toward greener, more efficient, integrated, and intelligent systems. Already deployed successfully across multiple industrial applications, the technology demonstrates excellent performance and reliability, filling a technical gap in the domestic market and offering a new sustainable solution for global industrial power systems.

Looking ahead, with continued deepening of foundational R&D, capacitor-free, highly integrated, and intelligent drive systems are set to become the industry standard, accelerating the shift toward safer, more efficient, and more sustainable industrial equipment.